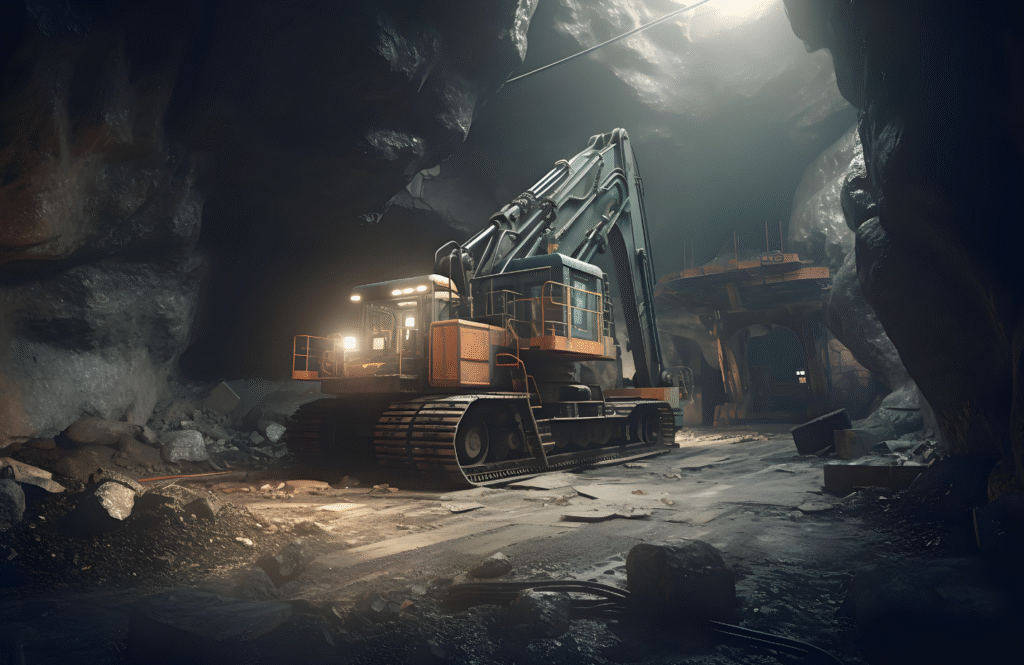

For decades, mining has been regarded as one of the world’s most hazardous occupations, where workers face unpredictable dangers—from unstable rock structures that can collapse without warning, to invisible toxic gases lurking in poorly ventilated tunnels, to massive machinery operating nearby, all within remote locations that delay emergency response. In such conditions, the vision of Zero-Harm Mining has often appeared more symbolic than achievable. Yet this reality is changing as Artificial Intelligence (AI) transforms how mines perceive, manage, and prevent safety risks. Today’s intelligent safety systems no longer function merely as reactive tools; instead, they act as predictive engines capable of detecting threats long before humans can sense them. By automating risk identification and embedding real-time intelligence into field operations, AI-driven safety platforms are redefining the future of mining, enabling a dramatic reduction in incidents, continuous visibility into risk, and a more consistent, resilient approach to safety.

Índice

Why Mining Remains Inherently Dangerous

Global safety data illustrates how persistent the challenge remains. The International Labour Organization estimates that mining employs just 1% of the global workforce but is responsible for roughly 8% of all work-related fatalities worldwide.

In the United States, the Mine Safety and Health Administration (MSHA) recorded 10 mining-related deaths between January 3 and March 5, 2025, more than tripling the number from the same period in 2024. Power-haulage incidents accounted for the majority, followed by machinery failures and falls at operation sites.

In South Africa, another major mining region, the Minerals Council reported 74 deaths in 2021 and 49 in 2022, underscoring that even regions with strict regulations continue to face systemic risks.

These long-term patterns reveal the limitations of traditional safety workflows. For example, silica dust is commonly monitored using handheld devices during scheduled checks. However, dust concentrations can spike significantly between inspections, leaving workers exposed for hours without anyone realizing it.

Human oversight has its limits: fatigue, workload pressure and environmental complexity can all reduce the effectiveness of manual monitoring. Historically, mining operations relied heavily on human supervision as the first line of defense. AI now offers the chance to convert that limited supervision into always-on safety intelligence.

The Rise of Intelligent Safety in Mining

Smart safety systems differ from traditional monitoring because they can process massive volumes of data instantly — and transform those signals into practical guidance.

For instance, an AI-enhanced CCTV network can identify whether miners entering a shaft are missing required PPE, eliminating delays and reducing the likelihood of human error. In deep underground operations, AI models can continuously evaluate seismic activity, rock-stress readings and airflow conditions, detecting early instability indicators that routine inspections often miss.

During emergencies such as gas leaks, modern AI systems deliver more than a generic alert. They automatically pinpoint the origin of the leak, highlight affected personnel and recommend immediate containment steps. This equips environmental, health and safety (EHS) teams with situational awareness that speeds up response times.

AI is also being adopted to monitor behavioral risks — factors often overlooked but strongly correlated with safety outcomes. At a major mining site in Ghana, an AI-based worker-interaction monitoring system led to a 62% reduction in aggressive incidents within three months. Fewer conflicts meant fewer disruptions, improved team cooperation and reduced secondary risks driven by stress or fatigue.

AI Adoption Accelerates Among Global Mining Leaders

Mining companies worldwide are already treating AI as a central pillar of operational transformation.

In Western Australia, a leading iron ore operation deployed autonomous haulage supported by machine learning, IoT sensors and real-time analytics to strengthen collision avoidance and incident prevention.

In Chile, AI-powered environmental and operational monitoring has helped conserve over 3 billion liters of water and 118 GWh of energy since 2022. Workers’ helmets now integrate physiological sensors that detect extreme fatigue—one of the strongest predictors of workplace accidents.

These examples demonstrate that AI is not a peripheral experiment. It is now embedded in operational policies, safety protocols and continuous-improvement cycles. Every AI deployment gives EHS leaders more insight into compliance performance and emerging risks.

Where Safety, Efficiency and Sustainability Converge

AI systems bring more than just accident prevention. They also reshape how efficiently and sustainably mining operations function.

Predictive maintenance powered by machine learning reduces unexpected equipment failures, prevents hazardous breakdowns and minimizes costly downtime. AI-regulated ventilation systems optimize airflow and reduce power consumption while maintaining safe atmospheric conditions underground.

For safety leaders, AI turns overwhelming raw data into intuitive dashboards, risk heat maps and predictive alerts. For frontline teams, the reassurance of continuous automated monitoring strengthens confidence — a critical component of a strong safety culture.

The visibility AI provides transforms safety from reactive to proactive. Risks that once remained hidden now surface instantly, giving teams the ability to intervene before danger escalates. This capability makes the goal of zero-harm mining more tangible than ever.

AI systems bring more than just accident prevention. They also reshape how efficiently and sustainably mining operations function.

Predictive maintenance powered by machine learning reduces unexpected equipment failures, prevents hazardous breakdowns and minimizes costly downtime. AI-regulated ventilation systems optimize airflow and reduce power consumption while maintaining safe atmospheric conditions underground.

For safety leaders, AI turns overwhelming raw data into intuitive dashboards, risk heat maps and predictive alerts. For frontline teams, the reassurance of continuous automated monitoring strengthens confidence — a critical component of a strong safety culture.

The visibility AI provides transforms safety from reactive to proactive. Risks that once remained hidden now surface instantly, giving teams the ability to intervene before danger escalates. This capability makes the goal of zero-harm mining more tangible than ever.

Rebuilding the Foundations of Safety Through AI

A frequent misconception is that AI replaces established safety processes. In reality, it amplifies them.

AI automation reduces repetitive administrative tasks, freeing compliance officers to focus on hazard prevention and strategic improvements. Real-time analytics let supervisors recognize developing risks immediately, without waiting for post-incident reports. Workers benefit from immediate feedback that reinforces safe behavior and strengthens training effectiveness.

This marks a shift in philosophy: safety is no longer a periodic checklist but a continuous, intelligence-driven layer of protection. For the first time, zero-harm mining is not just aspirational — it is operationally achievable.

The Digital Future of Mining Safety

The future of mining safety will be built on deeper AI integration. Digital twins will allow operators to model risk scenarios before deploying equipment or personnel. Smart IoT wearables will track fatigue, environmental exposure and proximity to hazards. Conversational AI assistants will help EHS teams access live site data through simple voice or text commands.

Mining companies now face a strategic decision: not whether to adopt AI, but how rapidly they can deploy it across sites and processes. Those who move decisively will enhance worker protection and position themselves as leaders in an industry where safety, sustainability and competitiveness are increasingly intertwined.

A Safer Mining Era Is Within Reach

Mining will never be entirely risk-free. However, advanced AI safety systems represent a major inflection point. They shift the industry from reacting to incidents toward preventing them, turning sporadic inspections into seamless, continuous oversight.

The mining sector has always thrived in the face of immense technical and environmental challenges — digging deeper, innovating faster and adapting continuously. Now, with AI at the center of safety strategy, the industry is redefining what protecting its workforce truly means.

Zero-harm mining is no longer a distant vision; it is becoming a measurable and achievable reality.