TruGem robot intelligent monitoring solution based on 5G industrial routers realizes efficient remote communication, real-time data collection and remote operation & maintenance, and helps the digital upgrade of production management.

背景

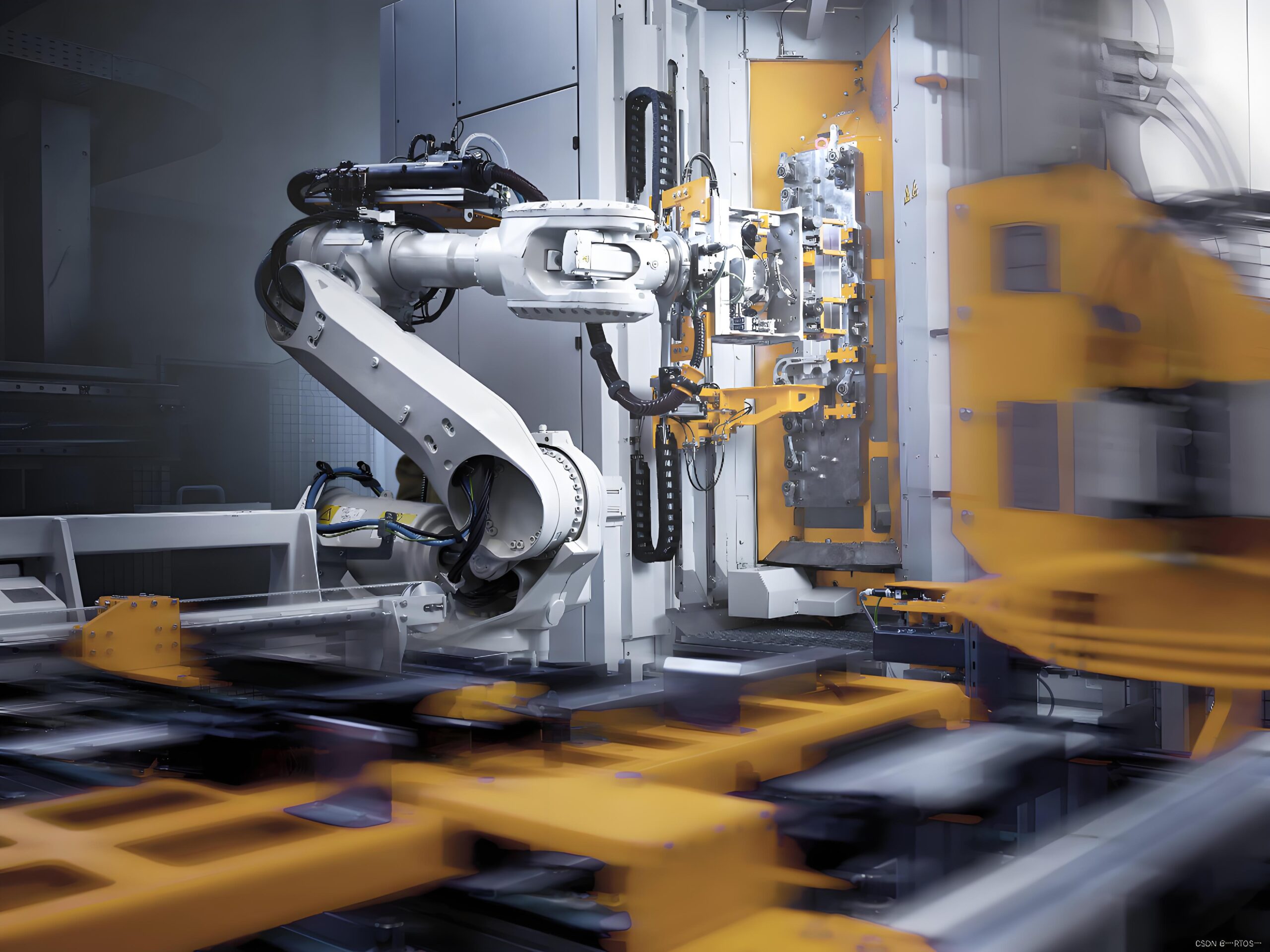

With the development of intelligent manufacturing, industrial robots play an increasingly important role in production lines and are widely used in welding, handling, assembly, packaging and other scenarios. Enterprises not only need robots to operate efficiently and stably, but also hope to achieve remote status control and operation & maintenance management of robots through digital means.

痛点

However, traditional industrial communication solutions have obvious bottlenecks in real-time, interconnectivity and remote operation and maintenance.

Lack of real-time monitoring capabilities

The robot’s operating status and information cannot be uploaded in real time, and it is difficult for operation & maintenance personnel to detect potential problems in time.

Limited remote maintenance

Traditional systems do not support remote debugging and control, resulting in delayed problem response and high maintenance costs.

Low data utilization

Production data is scattered and analysis is not timely, which makes it difficult to support accurate decision-making and production optimization.

解决方案

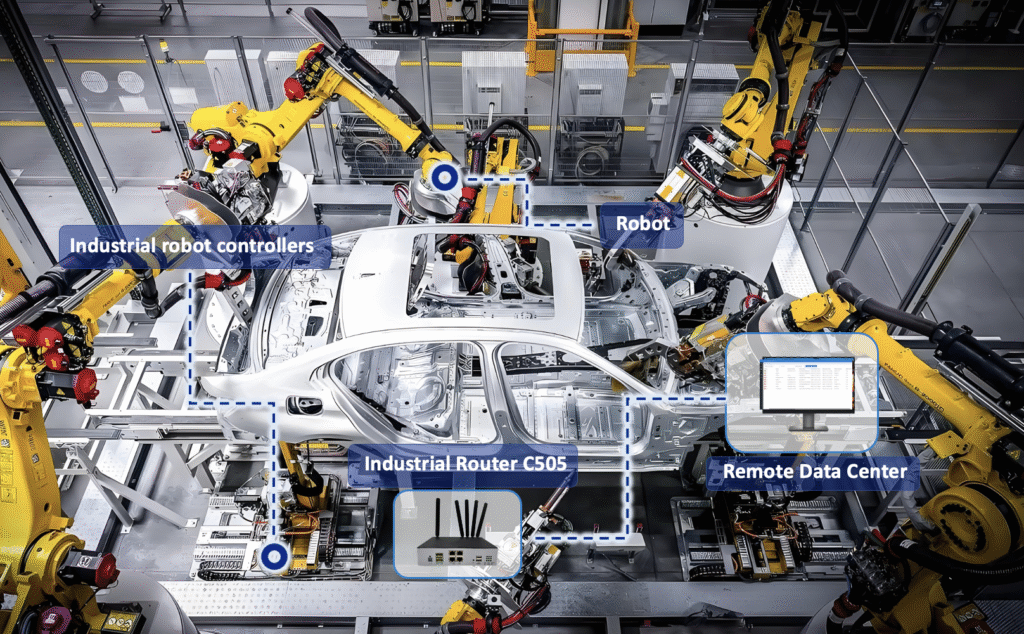

By integrating the 5G industrial router C505 into the industial robot intelligent monitoring solution, an efficient and reliable remote communication architecture is built. Industrial robot controllers, PLCs, and human-machine interaction systems can access C505 via Ethernet or serial ports to achieve centralized data collection and unified communication. C505 transmits robot working status data to the remote data center in real time through the Modbus TCP protocol. The data center can analyze the collected information and fully grasp key indicators such as robot operating efficiency, fault conditions, and maintenance cycles, thereby providing decision support for enterprises. At the same time, C505 supports connecting to the cloud platform and establishing a remote operation & maintenance channel, so that operation & maintenance personnel can debug, control, and upgrade on-site equipment at any location, improving the operation & maintenance response speed and the overall manageability of the system.

收益

Realize remote monitoring

Master the robot status around the clock, assist in preventive maintenance, and reduce the failure rate.

Improve O & M efficiency

Support remote debugging and diagnosis, reduce the number of manual visits, and reduce maintenance costs.

Enhance data value

Real-time collection and upload of key data for intelligent analysis and production optimization.

Adapt to complex environments

C505 supports 5G high-speed networks, industrial-grade interfaces and wide temperature design to meet the needs of harsh industrial scenarios.