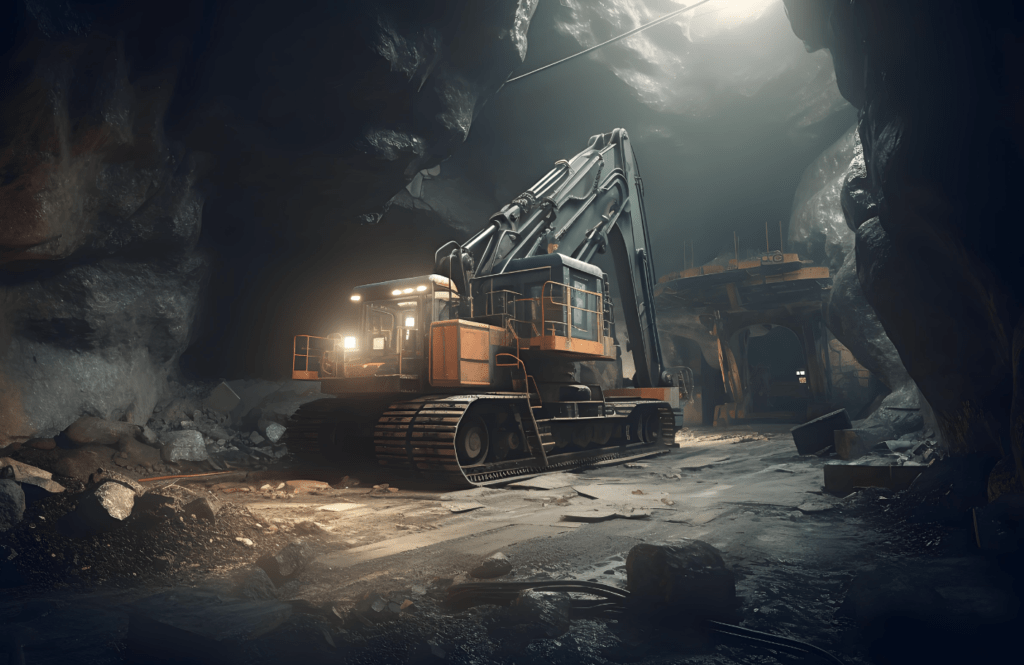

Mining operations are essential for global industries, but they also pose significant environmental challenges. Airborne dust, toxic gases, and fluctuating weather conditions can impact worker safety and regulatory compliance. Traditional monitoring methods are often reactive, inefficient, and lack real-time insights. However, IoT sensors are revolutionizing mining environmental monitoring, offering data-driven solutions for safety, compliance, and sustainability.

Table of contents

The Need for Environmental Monitoring in Mining

Mining environments generate high levels of dust, leading to air pollution, equipment degradation, and health risks such as respiratory diseases. Conventional monitoring relies on periodic manual sampling, which is time-consuming and fails to provide real-time data. IoT-powered mining environmental monitoring continuously tracks dust levels, hazardous gases, and weather conditions, enabling proactive measures.

IoT Dust Sensors: How They Work

IoT dust sensors utilize advanced detection technologies, including:

- Laser Scattering & Optical Sensing: Detects particulate matter (PM2.5, PM10) in real-time.

- Gas Sensors: Measures harmful gases like CO, SO2, and NOx.

- Wireless Connectivity (LoRa, NB-IoT, 5G): Transmits data to centralized monitoring platforms.

- AI and Cloud Integration: Enables predictive analytics and automated alerts.

These sensors can be deployed across mining sites, generating real-time data that enhances decision-making.

Transformative Applications of IoT in Mining Environmental Monitoring

Real-Time Dust Monitoring for Worker Safety

Mining workers are exposed to high levels of dust, leading to long-term health risks. IoT dust sensors provide:

- Continuous air quality monitoring to ensure compliance with occupational safety standards.

- Automated alerts when dust levels exceed safe thresholds.

- Wearable sensor integration for personalized worker protection.

Data-Driven Pollution Source Tracking

Identifying the sources of pollution is crucial for regulatory compliance. IoT-powered monitoring systems:

- Use real-time geotagged data to pinpoint pollution sources.

- Provide historical data analysis to assess long-term environmental impact.

- Help in implementing targeted dust control measures.

Automated Dust Suppression & Control

IoT sensors can be integrated with automated systems to manage dust levels efficiently:

- Smart water spray systems activate when high dust levels are detected.

- AI-driven predictive analytics optimize dust control measures.

- Remote monitoring capabilities reduce manual intervention.

The Future of Smart Mining: AI, 5G, and Cloud Integration

The future of mining environmental monitoring lies in the seamless integration of AI, IoT, and cloud computing:

- AI-powered analytics can predict dust patterns and recommend preventive actions.

- 5G connectivity ensures real-time data transmission for remote mines.

- Cloud-based platforms provide centralized dashboards for large-scale monitoring.

These advancements will enable data-driven decision-making, improving safety, efficiency, and compliance.

Conclusion: A Smarter, Safer Mining Industry

By adopting IoT sensors and data-driven monitoring, the mining industry can transition from reactive to proactive environmental management. These technologies not only enhance worker safety but also improve regulatory compliance and operational efficiency. As mining evolves, IoT-powered environmental monitoring will be the key to building a more sustainable and responsible industry.