يحقق حل المراقبة الذكي للروبوت TruGem القائم على أجهزة التوجيه الصناعية 5G اتصالاً فعالاً عن بُعد، وجمع البيانات في الوقت الحقيقي والتشغيل والصيانة عن بُعد، ويساعد على الترقية الرقمية لإدارة الإنتاج.

الخلفية

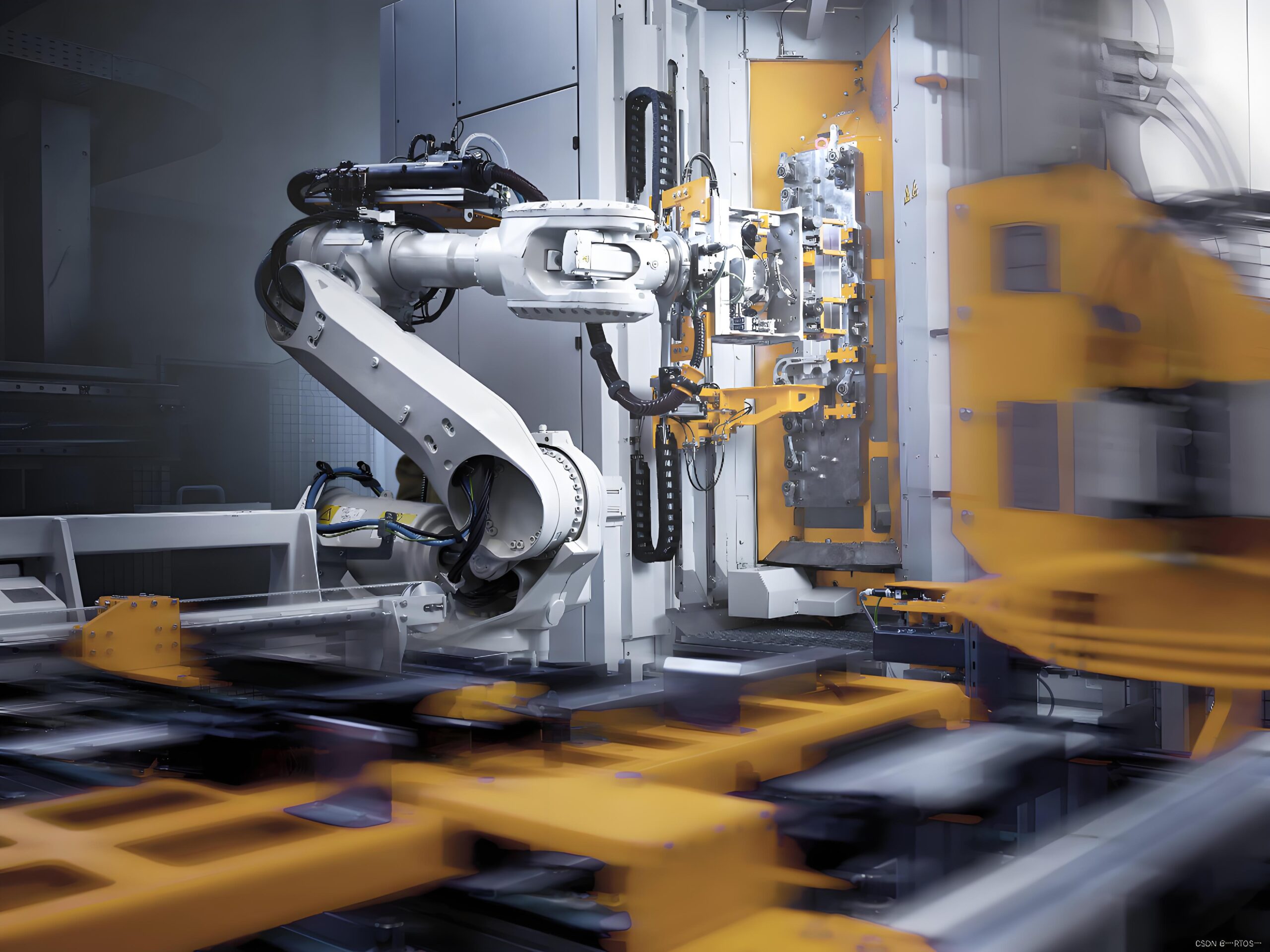

مع تطور التصنيع الذكي، تلعب الروبوتات الصناعية دورًا متزايد الأهمية في خطوط الإنتاج وتستخدم على نطاق واسع في اللحام والمناولة والتجميع والتعبئة والتغليف وغيرها من السيناريوهات. لا تحتاج الشركات إلى أن تعمل الروبوتات بكفاءة وثبات فحسب، بل تأمل أيضًا في تحقيق التحكم في حالة الروبوتات عن بُعد وإدارة تشغيلها وصيانتها من خلال الوسائل الرقمية.

نقاط الألم

ومع ذلك، فإن حلول الاتصالات الصناعية التقليدية تعاني من اختناقات واضحة في الوقت الحقيقي والربط البيني والتشغيل والصيانة عن بُعد.

الافتقار إلى قدرات المراقبة في الوقت الحقيقي

لا يمكن تحميل حالة تشغيل الروبوت ومعلوماته في الوقت الفعلي، ومن الصعب على موظفي التشغيل والصيانة اكتشاف المشاكل المحتملة في الوقت المناسب.

صيانة محدودة عن بُعد محدودة

لا تدعم الأنظمة التقليدية تصحيح الأخطاء والتحكم عن بُعد، مما يؤدي إلى تأخر الاستجابة للمشاكل وارتفاع تكاليف الصيانة.

انخفاض استخدام البيانات

بيانات الإنتاج مبعثرة ولا يتم تحليلها في الوقت المناسب، مما يجعل من الصعب دعم اتخاذ القرارات الدقيقة وتحسين الإنتاج.

الحل

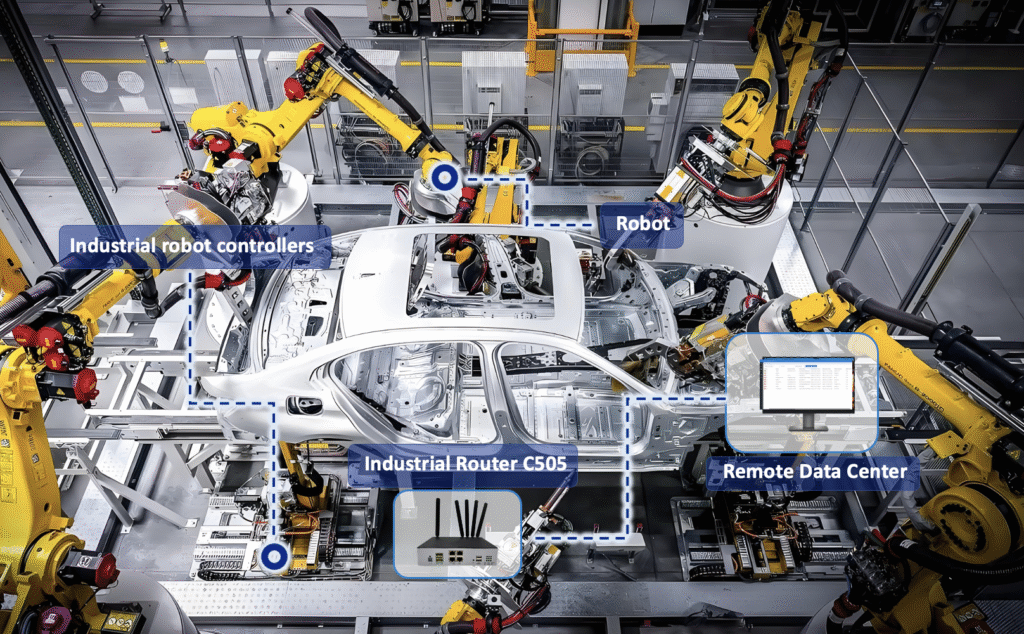

من خلال دمج جهاز التوجيه الصناعي C505 من الجيل الخامس 5G في حل المراقبة الذكية للروبوتات الصناعية، تم بناء بنية اتصالات عن بُعد فعالة وموثوقة. يمكن لوحدات التحكم في الروبوتات الصناعية وأجهزة التحكم المنطقي القابلة للبرمجة وأنظمة التفاعل بين الإنسان والآلة الوصول إلى C505 عبر الإيثرنت أو المنافذ التسلسلية لتحقيق جمع مركزي للبيانات واتصالات موحدة. تنقل C505 بيانات حالة عمل الروبوت إلى مركز البيانات عن بُعد في الوقت الفعلي من خلال بروتوكول Modbus TCP. يمكن لمركز البيانات تحليل المعلومات التي تم جمعها وفهم المؤشرات الرئيسية مثل كفاءة تشغيل الروبوت وظروف الأعطال ودورات الصيانة بشكل كامل، وبالتالي توفير دعم اتخاذ القرار للمؤسسات. وفي الوقت نفسه، يدعم C505 الاتصال بالمنصة السحابية وإنشاء قناة للتشغيل والصيانة عن بُعد، بحيث يمكن لموظفي التشغيل والصيانة تصحيح أخطاء المعدات في الموقع والتحكم فيها وترقيتها في أي مكان، مما يحسن سرعة استجابة التشغيل والصيانة وإمكانية إدارة النظام بشكل عام.

المزايا

تحقيق المراقبة عن بُعد

إتقان حالة الروبوت على مدار الساعة والمساعدة في الصيانة الوقائية وتقليل معدل الأعطال.

تحسين كفاءة التشغيل والصيانة

دعم تصحيح الأخطاء والتشخيص عن بُعد، وتقليل عدد الزيارات اليدوية، وتقليل تكاليف الصيانة.

تعزيز قيمة البيانات

جمع البيانات الرئيسية وتحميلها في الوقت الحقيقي من أجل التحليل الذكي وتحسين الإنتاج.

التكيف مع البيئات المعقدة

تدعم C505 شبكات 5G عالية السرعة، وواجهات من الدرجة الصناعية، وتصميمًا واسعًا لدرجات الحرارة العالية لتلبية احتياجات السيناريوهات الصناعية القاسية.