5G LAN is emerging as a critical foundation for the next generation of smart factories. As manufacturing environments evolve toward higher automation, flexible production lines, and data-driven decision-making, traditional industrial networks are reaching their limits.

For decades, factories have relied on a combination of industrial Ethernet and Wi-Fi. While wired networks offer stability, they lack flexibility. Wi-Fi, on the other hand, provides mobility but often struggles with interference, roaming issues, and unpredictable latency. As a result, manufacturers face a growing gap between operational requirements and network capabilities.

At the same time, modern factories are deploying more mobile equipment, real-time control systems, machine vision, and AI-driven applications. These workloads demand deterministic low-latency communication, high reliability, and strong security—requirements that conventional networks were not designed to meet.

C'est ici que RÉSEAU LOCAL 5G comes into play. By bringing 5G technology into a local area network architecture, 5G LAN enables factories to build a wireless network that behaves like a wired LAN, while retaining the flexibility of wireless communication.

Table des matières

- What Is 5G LAN and How Is It Different?

- The Networking Challenges of Modern Smart Factories

- Why 5G LAN Fits Industrial Manufacturing Environments

- Key Factory Use Cases Enabled by 5G LAN

- Security and Network Isolation in 5G LAN

- Integration with Edge Computing and AI

- Comparing 5G LAN with Wi-Fi and Industrial Ethernet

- Deployment Considerations for Factory 5G LAN

- The Future of 5G LAN in Manufacturing

- Conclusion: 5G LAN as a Strategic Industrial Investment

What Is 5G LAN and How Is It Different?

Before exploring factory applications, it is important to clarify what 5G LAN actually means in an industrial context.

A 5G LAN is a local, enterprise-grade 5G network deployed within a factory or industrial site. Unlike public 5G services, it operates as a private or dedicated network and integrates seamlessly with existing IP-based industrial systems.

Key characteristics of 5G LAN include:

- LAN-like architecture: Devices communicate using standard IP networking, similar to Ethernet-based LANs.

- Deterministic performance: Support for ultra-low latency and predictable communication behavior.

- Haute fiabilité: Designed for mission-critical industrial applications.

- Secure isolation: Traffic remains within the factory network, separated from public networks.

- Wireless flexibility: No physical cables are required for device connectivity.

In practice, 5G LAN allows factories to treat wireless devices as first-class citizens within their industrial IoT infrastructure, rather than as unreliable add-ons.

The Networking Challenges of Modern Smart Factories

To understand the value of 5G LAN, it helps to examine the specific challenges that smart factories face today.

Increasing Device Mobility

Modern production lines are no longer static. Factories increasingly rely on:

- Automated Guided Vehicles (AGVs)

- Autonomous Mobile Robots (AMRs)

- Mobile inspection and maintenance tools

These devices must move freely across production areas while maintaining stable communication. Traditional wired networks cannot support this mobility, and Wi-Fi roaming often introduces latency and packet loss.

Real-Time Control Requirements

Industrial automation systems such as PLCs, robotic arms, and motion controllers require real-time communication. Even small delays can affect production quality or cause safety risks. However, best-effort wireless networks cannot guarantee consistent latency under heavy load.

Network Complexity and Maintenance Costs

Many factories operate multiple parallel networks:

- Industrial Ethernet for control systems

- Wi-Fi for mobile terminals

- Field bus systems for legacy equipment

This fragmented approach increases operational complexity and maintenance costs. Integrating new systems often requires extensive re-cabling or network redesign.

Security and Data Isolation

Factories handle sensitive production data and proprietary processes. Sending industrial traffic over public networks or poorly secured wireless systems introduces unacceptable security risks.

Why 5G LAN Fits Industrial Manufacturing Environments

5G LAN directly addresses these challenges by combining the strengths of cellular technology with enterprise LAN principles.

Deterministic Low-Latency Communication

One of the most significant advantages of 5G LAN is its ability to provide deterministic low-latency network performance. With features such as URLLC (Ultra-Reliable Low-Latency Communication), factories can support time-sensitive industrial applications over wireless links.

This capability makes 5G LAN suitable for:

- Motion control systems

- Real-time robotics coordination

- Synchronized production processes

Unlike Wi-Fi, which operates on a contention-based mechanism, 5G LAN uses scheduled communication, enabling predictable performance even under high device density.

Seamless Mobility for AGVs and AMRs

AGV and AMR connectivity is one of the most common use cases for 5G LAN in factories. Mobile robots require continuous, reliable communication for navigation, task coordination, and safety functions.

With 5G LAN, AGVs and AMRs benefit from:

- Seamless handover between base stations

- Stable latency during movement

- High bandwidth for sensor data and video streams

As a result, factories can scale mobile automation without redesigning their network infrastructure.

Simplified Network Architecture

By replacing multiple wireless and wired systems, 5G LAN enables a more unified smart factory networking architecture. Industrial devices, mobile equipment, and IoT sensors can all connect through the same local 5G network.

This consolidation reduces:

- Cabling complexity

- Network management overhead

- Deployment time for new production lines

Moreover, integration with existing Ethernet and industrial protocols ensures compatibility with legacy systems.

Key Factory Use Cases Enabled by 5G LAN

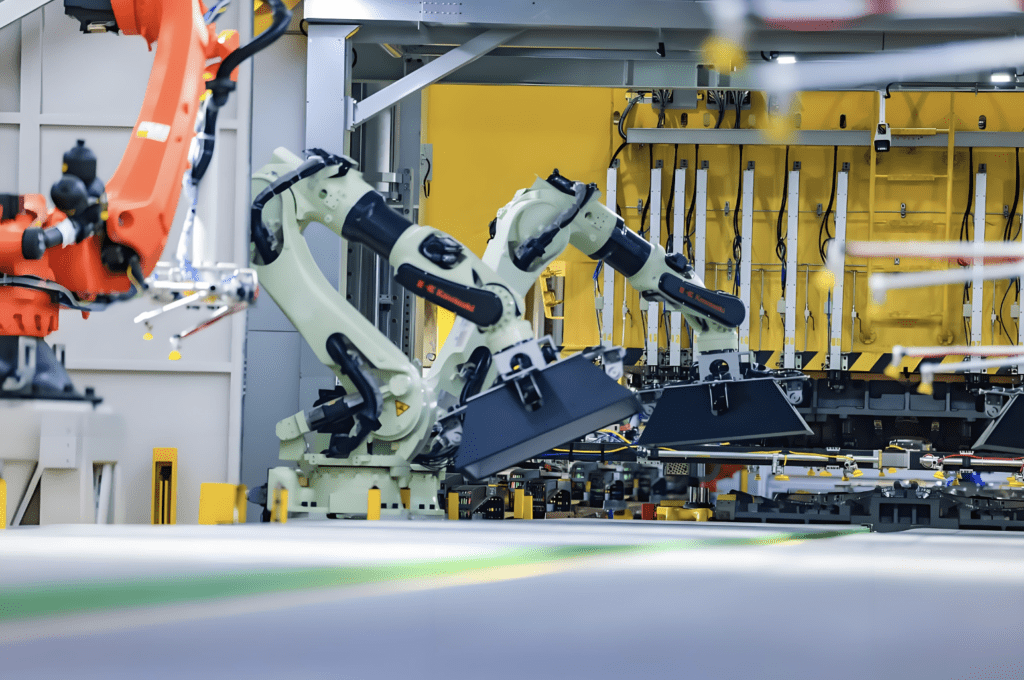

Industrial Robotics and Automation

Robots are becoming more intelligent, collaborative, and mobile. They rely on high-speed communication for coordination, sensor fusion, and real-time control.

With 5G LAN, factories can:

- Enable wireless robot control without sacrificing reliability

- Support collaborative robots (cobots) in dynamic environments

- Reduce downtime caused by cable wear and failure

This shift also allows greater flexibility in production line design and reconfiguration.

Machine Vision and Quality Inspection

Machine vision systems generate large volumes of image and video data. Transmitting this data reliably and in real time is critical for quality control.

5G LAN supports machine vision by providing:

- High uplink bandwidth for image transmission

- Low latency for real-time inspection feedback

- Stable performance in electromagnetically noisy environments

When combined with edge computing, 5G LAN enables on-site AI analysis without sending sensitive data to the cloud.

Predictive Maintenance and Industrial IoT

Factories increasingly rely on industrial wireless communication to connect sensors that monitor equipment health, vibration, temperature, and energy consumption.

5G LAN enhances predictive maintenance by:

- Supporting massive sensor connectivity

- Ensuring reliable data transmission

- Enabling real-time alerts and diagnostics

As part of a broader industrial IoT infrastructure, 5G LAN helps manufacturers move from reactive maintenance to predictive and condition-based strategies.

Flexible and Modular Production Lines

Market demand for customized products is driving the adoption of flexible manufacturing. Production lines must be reconfigured frequently to accommodate new products or processes.

With 5G LAN:

- New machines can be connected without laying new cables

- Temporary production cells can be deployed quickly

- Network changes do not disrupt ongoing operations

This flexibility significantly reduces time-to-market and supports agile manufacturing strategies.

Security and Network Isolation in 5G LAN

Security is a core requirement in industrial environments. 5G LAN is designed with multiple layers of protection to safeguard factory operations.

Key security features include:

- SIM-based device authentication

- Encrypted communication at the radio and core network levels

- Logical network isolation through slicing or dedicated cores

Unlike public wireless networks, a factory’s 5G LAN keeps all traffic within the local domain. This design minimizes exposure to external threats and ensures compliance with industrial cybersecurity standards.

Integration with Edge Computing and AI

5G LAN does not operate in isolation. Its real value emerges when combined with edge computing platforms.

By placing computing resources close to the production floor, factories can:

- Process data locally with minimal latency

- Run AI models for vision, anomaly detection, and optimization

- Reduce dependency on cloud connectivity

In this architecture, 5G LAN acts as the high-performance data pipeline that connects machines, sensors, and edge intelligence into a cohesive system.

Comparing 5G LAN with Wi-Fi and Industrial Ethernet

While Wi-Fi and Ethernet will continue to play important roles, 5G LAN fills a critical gap in industrial networking.

| Fonctionnalité | Industrial Ethernet | Wi-Fi | RÉSEAU LOCAL 5G |

|---|---|---|---|

| Mobilité | Aucun | Limited | Full |

| Temps de latence | Very low | Variable | Deterministic |

| Fiabilité | Haut | Medium | Very high |

| Évolutivité | Modéré | Limited | Haut |

| Sécurité | Haut | Medium | Haut |

This comparison highlights why many manufacturers view 5G LAN as a complementary technology rather than a complete replacement. In practice, hybrid architectures are common, with 5G LAN handling mobile and time-sensitive workloads.

Deployment Considerations for Factory 5G LAN

While the benefits are clear, successful deployment requires careful planning.

Manufacturers should consider:

- Coverage planning based on factory layout

- Integration with existing IT and OT systems

- Device compatibility and certification

- Long-term scalability and maintenance

Working with experienced system integrators and solution providers is often essential to ensure a smooth transition.

The Future of 5G LAN in Manufacturing

As Industry 4.0 continues to evolve, the role of 5G LAN in factories will expand further. Upcoming developments include:

- Tighter integration with time-sensitive networking (TSN)

- Enhanced support for ultra-critical control applications

- Deeper convergence with AI-driven manufacturing systems

In the long term, 5G LAN will become a foundational element of smart factory networking, enabling manufacturers to operate with greater efficiency, flexibility, and resilience.

Conclusion: 5G LAN as a Strategic Industrial Investment

5G LAN is not just another wireless technology. It represents a strategic shift in how factories design and operate their networks. By delivering deterministic performance, secure local connectivity, and unmatched flexibility, 5G LAN empowers manufacturers to meet the demands of modern industrial production.

For factories seeking to scale automation, deploy mobile robotics, and build a future-ready industrial IoT infrastructure, 5G LAN provides a robust and practical networking foundation.

Rather than replacing existing systems overnight, 5G LAN enables a gradual and controlled evolution toward truly intelligent manufacturing environments.