BMW a officiellement lancé la première Usine pilotée par l'IA à Debrecen, en Hongrie, marquant ainsi une étape importante pour l'industrie automobile mondiale. Avec un investissement de près de 2 milliards d'euros, ce site est la base de production la plus avancée et la plus durable de BMW à ce jour.

Derrière cette innovation se cache un facilitateur technologique crucial : le système de gestion de l'information. Connectivité 5G. Soutenue par un réseau 5G hybride robuste, l'usine BMW pilotée par l'IA fonctionne de manière transparente avec des capteurs interconnectés, des robots et des analyses basées sur le cloud. Cette collaboration entre IA et 5G établit une nouvelle référence pour les systèmes d'information de nouvelle génération. fabrication automobile intelligente.

Table des matières

- La 5G : l'épine dorsale de la première usine de voitures intelligentes au monde

- Le rôle des réseaux hybrides 5G dans la mise en œuvre des opérations d'IA

- L'automatisation basée sur la technologie 5G transforme la logistique des usines

- Un élan mondial : la 5G + l'IA deviennent la nouvelle norme pour la fabrication automobile intelligente

- L'expansion des réseaux privés 5G dans tous les secteurs d'activité

- La 5G et l'IA : au cœur de la fabrication automobile intelligente de la prochaine génération

La 5G : l'épine dorsale de la première usine de voitures intelligentes au monde

BMW décrit l'installation de Debrecen comme sa première une usine entièrement pilotée par l'IA, sans énergie fossile et jumelée numériquement - entièrement alimenté par des énergies renouvelables. Des algorithmes d'IA régissent chaque étape du processus de production, ce qui permet d'obtenir des résultats en temps réel. le contrôle de la qualité, processus optimisationet maintenance prédictive.

Avant qu'une seule pièce automobile ne soit assemblée, le véhicule subit les opérations suivantes simulation virtuelle et numérique validation à l'aide d'une combinaison de caméras, de capteurs IoT et de modèles d'apprentissage automatique. Cet environnement de jumeau numérique détecte les défauts tels que incohérences dans la peinture ou désalignement des composants en temps réel, garantissant ainsi la précision avant le début de l'assemblage.

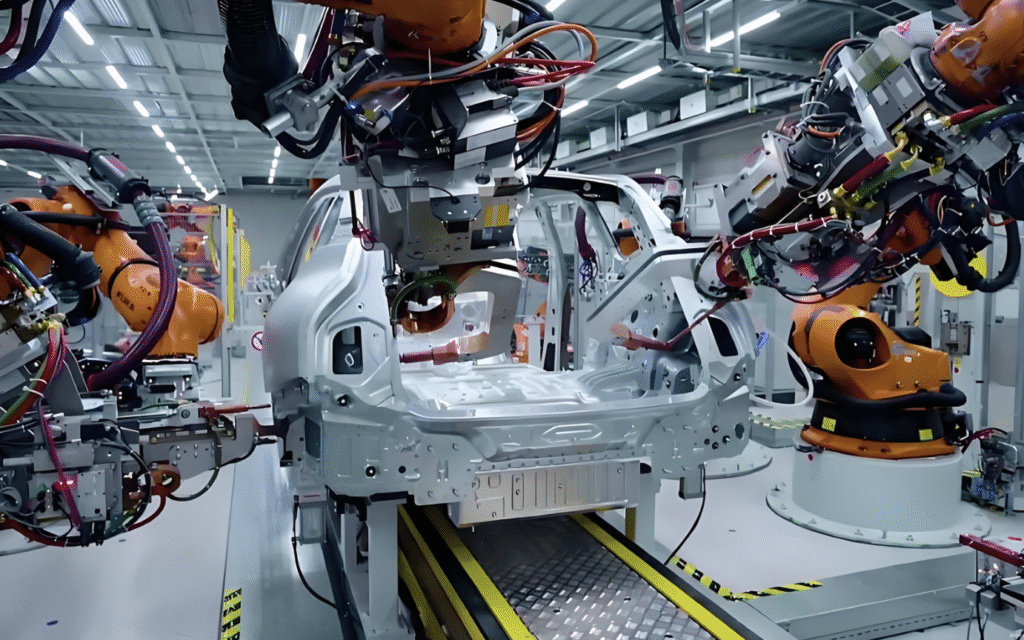

Plus de 1 000 robots industriels, guidés par des opérateurs humains experts, assemblent chaque voiture avec une rapidité et une précision exceptionnelles. L'usine produira la prochaine génération de véhicules électriques (VE), y compris les BMW iX3 - offrant une gamme de produits allant jusqu'à 500 milles - dans le cadre du programme BMW Nouvelle classe dont la production devrait commencer à la fin du mois d'octobre.

Le rôle des réseaux hybrides 5G dans la mise en œuvre des opérations d'IA

Selon les analystes de SNS Télécommunications et technologies de l'information, L'usine de Debrecen fonctionne sur la base d'un système d'alimentation en eau potable. infrastructure hybride 5G construit par Magyar Telekom, le plus grand opérateur de télécommunications de Hongrie. Contrairement aux réseaux privés traditionnels, l'approche de BMW intègre à la fois couches publiques et privées de la 5G, L'objectif est d'atteindre un équilibre entre couverture, fiabilité et rentabilité.

S'étendant sur une zone de 400 hectares, Avec une couverture intérieure de 15%, le système hybride permet d'interconnecter des milliers d'ordinateurs portables. caméras, tablettes, capteurs et robots autonomes sur l'ensemble du site. Presque 1 000 robots industriels compter sur la 5G pour communication ultra-fiable à faible latence (URLLC), garantissant la synchronisation des opérations et réduisant au minimum les temps d'arrêt.

Au cœur de l'écosystème d'IA de BMW se trouvent AIQX, l'entreprise Plateforme d'inspection de la qualité par l'IA de nouvelle génération. Ce système basé sur le cloud utilise des capteurs visuels et acoustiques pour détecter automatiquement les erreurs d'assemblage, les pièces manquantes et les défauts de surface. AIQX analyse les données de production en temps réel et alerte immédiatement le personnel en cas d'anomalie, garantissant ainsi une qualité de produit irréprochable.

Un tel contrôle de précision serait impossible sans en temps réel 5G connectivité, qui fournit les informations nécessaires à l'élaboration d'un plan d'action. bande passante et le temps de latence pour gérer les flux de données massifs et à grande vitesse entre les appareils périphériques et les systèmes en nuage.

L'automatisation basée sur la technologie 5G transforme la logistique des usines

L'usine de Debrecen démontre également comment communication sans fil peut redéfinir la logistique et la manutention.

Transport par véhicules guidés automatisés (AGV) batteries haute tension pour véhicules électriques directement à partir des installations d'assemblage de batteries adjacentes, tandis que robots de transport intelligents livrer de manière autonome des pièces plus petites à des postes de travail spécifiques. Ce système suit un “structure des doigts”La disposition de l'écran permet d'avoir jusqu'à 80% de tous les matériaux de la livraison directement à leur point d'assemblage, ce qui a été rendu possible grâce à la mise en place d'un système de gestion de l'information. 5G de haute qualité et ininterrompue connectivité.

La collaboration sans faille entre Réseaux 5G et AI l'automatisation garantit que les processus logistiques sont non seulement efficaces, mais aussi adaptables aux fluctuations de la production, ce qui améliore considérablement le débit et l'utilisation des ressources.

L'élan mondial : 5G + IA devient la nouvelle norme en matière de fabrication automobile intelligente

BMW n'est pas le seul à avoir adopté la 5G pour la fabrication intelligente. Depuis les premiers stades de la commercialisation de la 5G, de grands constructeurs automobiles tels que Tesla, Mercedes-Benzet Porsche ont également déployé des réseaux privés 5G pour améliorer l'automatisation et la sécurité.

En août 2024, Tesla a lancé une Réseau privé 5G à son Gigafactory de Shanghai, après un déploiement similaire en Berlin trois mois plus tôt. Selon l'équipe informatique de Tesla à Berlin,

“Le réseau 5G dédié jette les bases de l'innovation dans la fabrication, l'entreposage et les opérations de nouvelle génération. Il permet à nos systèmes mobiles de communiquer de manière fiable et de maintenir un flux de travail continu.”

L'expérience de Tesla met en évidence un changement global - où l'on voit que l'on ne peut pas se passer de l'expérience de Tesla. Réseaux privés 5G constituent l'épine dorsale des chaînes de production automobile de la prochaine génération. De même, les modèle hybride 5G démontre comment une architecture mixte peut garantir la sécurité, l'évolutivité et l'interopérabilité tout en maintenant les coûts à un niveau raisonnable.

L'expansion des réseaux privés 5G dans tous les secteurs d'activité

En Chine, 5G+ Internet industriel est entré dans une phase d'accélération rapide. Depuis le Juin 2025, il y a plus de 18 500 projets industriels 5G à l'échelle nationale et 58 000 réseaux 5G privés virtuels déployés dans des secteurs tels que l'industrie manufacturière, les ports, les soins de santé et l'énergie.

La plupart de ces réseaux fonctionnent actuellement comme Réseaux privés virtuels (VPN) 5G gérés par les opérateurs de télécommunications, ce qui permet aux clients industriels d'utiliser l'infrastructure publique tout en maintenant l'isolation logique et la transmission sécurisée des données.

Cependant, l'écosystème évolue. En tant que réseaux 5G privés indépendants Afin d'améliorer la rentabilité et la modularité de leurs systèmes, les petites et moyennes entreprises (PME) commencent à déployer leurs propres systèmes dédiés. Cette évolution devrait avoir de profondes répercussions sur les opérateurs de télécommunications, qui seront amenés à étendre leurs services de téléphonie mobile. TIC portefeuilles en intégrant l'informatique en nuage (cloud computing), AIet big data services dans les solutions industrielles 5G.

La 5G et l'IA : au cœur de la fabrication automobile intelligente de la prochaine génération

L'usine BMW pilotée par l'IA met en lumière une transformation plus large qui balaie le secteur manufacturier - la convergence des technologies de l'information et de la communication (TIC) et des technologies de l'information et de la communication. Connectivité 5G, intelligence artificielle, et l'automatisation. Ensemble, ils créent un environnement de production très réactif où chaque processus est mesurable, adaptable et fondé sur des données.

Le succès de l'usine de Debrecen démontre que la 5G n'est plus seulement une norme de communication, c'est l'avenir. les fondements de l'intelligence industrielle. Grâce à sa capacité à fournir synchronisation en temps réel, transmission ultra-fiable et mise à l'échelle flexible, Avec la 5G, les écosystèmes complexes pilotés par l'IA peuvent fonctionner à plein régime.

Au fur et à mesure que les fabricants adoptent des architectures similaires, 5G + usine pilotée par l'IA redéfinira les modèles de production mondiaux, en établissant de nouvelles normes en matière de durabilité, de précision et d'efficacité.