Intelligent monitoring and O&M solution for distribution station collects data through various sensors and transmits it to the TruGem All-in-One Edge Computing Gateway in real time. The operation and maintenance personnel can use the platform to grasp the status and operation data of security, environment, equipment, etc. remotely. The platform can also provide real-time alarms and linkage control for abnormalities.

Background

As an important hub at the end of the power system, the distribution station undertakes the final transformation and distribution of electric energy. Its operation stability is directly related to the power supply reliability of the power grid and the safety of people’s lives and property. With the acceleration of urbanization, the number of distribution stations continues to grow, showing the characteristics of multiple points, wide coverage, dense equipment, and complex environment.

Pain points

Lack of real-time monitoring and frequent safety hazards

Distribution stations generally lack real-time monitoring methods for the environment and equipment. Abnormal temperature and humidity, excessive harmful gases cannot be discovered in time, and equipment overload or short circuit can easily cause electrical fires. Misoperation by personnel and failure to wear protective equipment may also cause personal accidents such as electric shock, which seriously threatens the safety of distribution stations.

Conventional operation and maintenance methods are inefficient and costly

Relying on manual on-duty and regular inspections not only has high labor costs, but also makes it difficult to continuously and efficiently discover equipment hidden dangers. Once a fault occurs, untimely response and irregular handling procedures can easily cause large-scale power outages and safety accidents.

Weak digital capabilities and severe system silos

Most distribution stations lack unified technical standards, making data sharing and unified management difficult. The low level of intelligence and visualization makes it difficult to support refined and predictive operation and maintenance management.

Solution

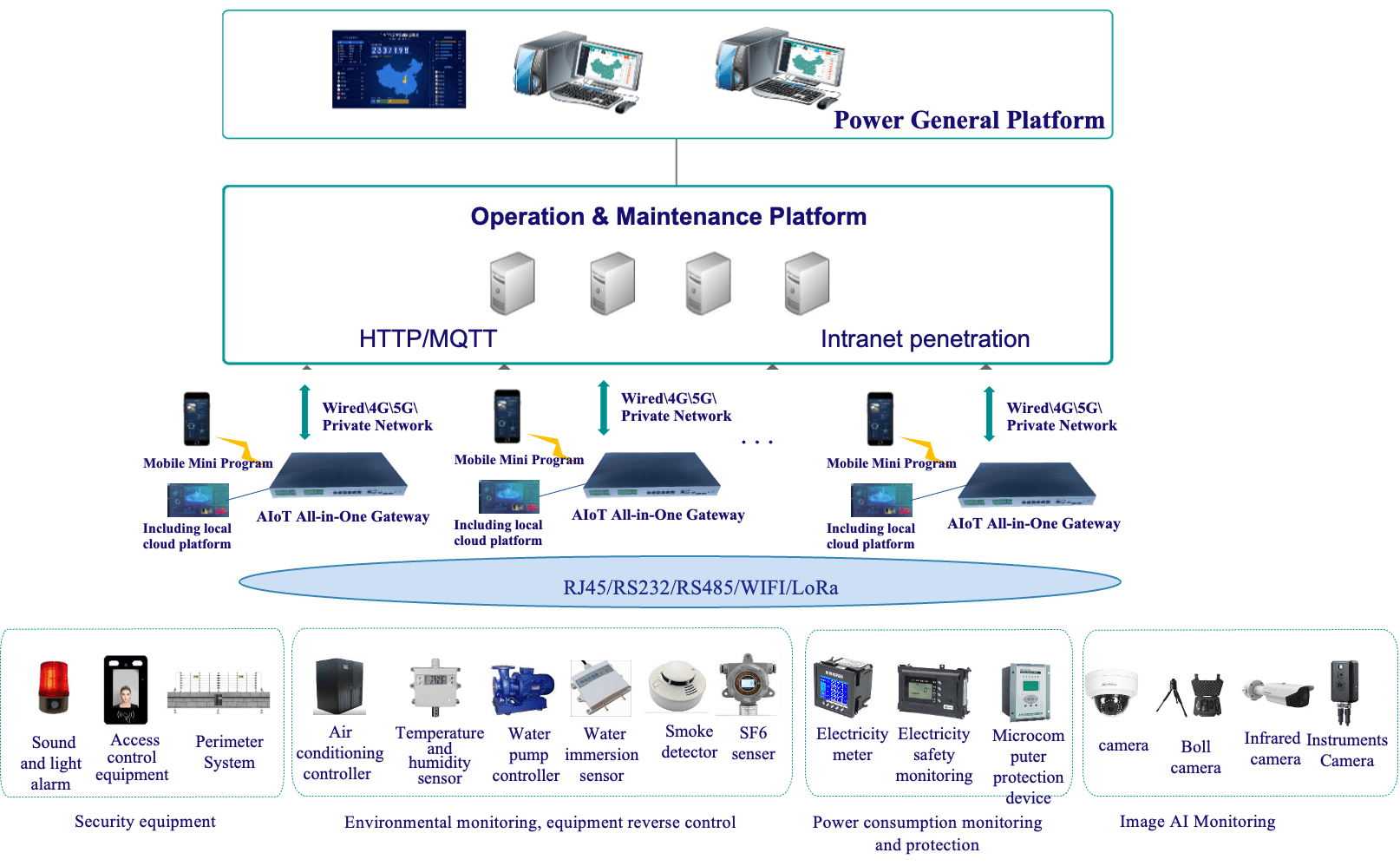

TruGem’s Intelligent Monitoring and O&M Solution for distribution station builds a visible, manageable and controllable intelligent operation and maintenance system through intelligent perception, edge computing, cloud platforms and unified management.

Solution Core components:

- Lower-end intelligent perception devices: Deploy access control and other security equipment, temperature and humidity sensors, SF6, O₃ and other environmental monitoring sensors, electrical parameter monitoring devices and cameras, etc., to collect environmental and power operation data in real time.

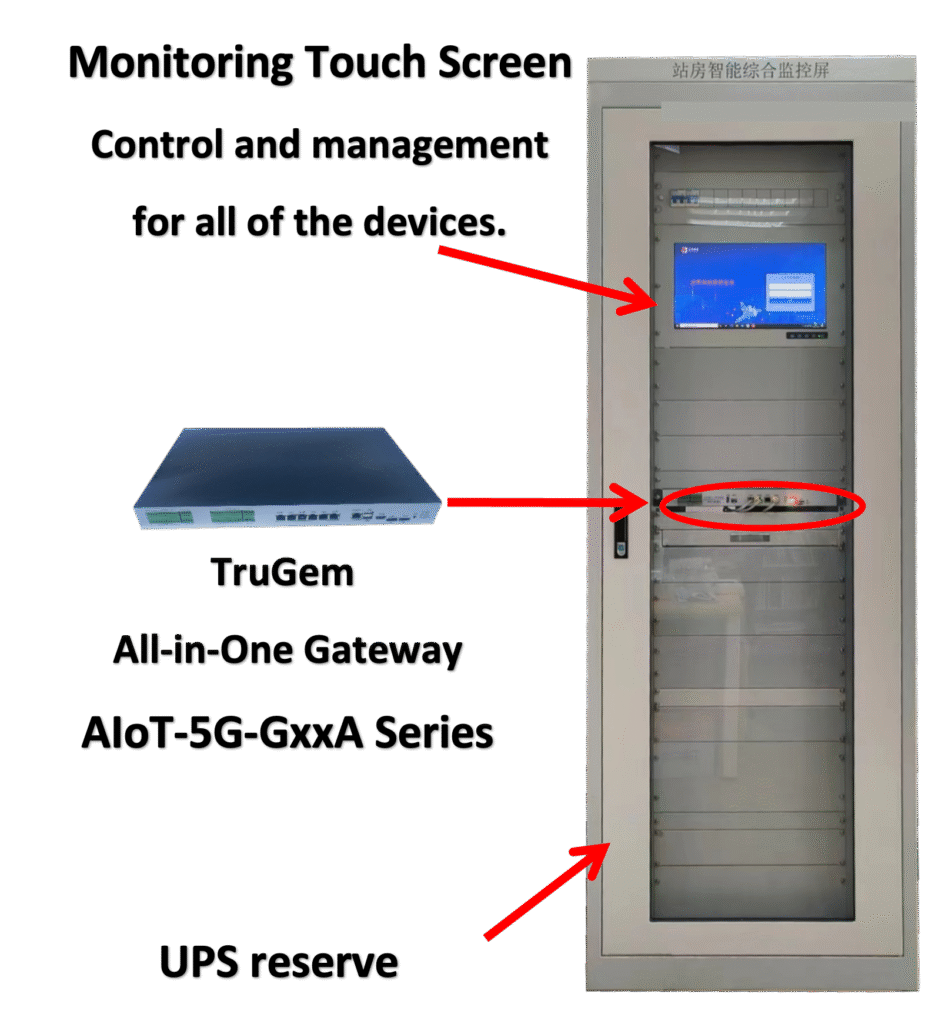

- Intelligent gateway equipment: With the TruGem’s multi-interface industrial-grade intelligent All-in-One Edge Computing Gateway AIoT-5G-G06 as the core, it supports multiple communication interfaces such as RS232, RS485, RJ45, DIDO, and USB, achieving unified data collection and protocol adaptation for various types of devices.

- Power IoT platform: The platform centrally displays various operation data, achieving functions such as abnormal alarm, video linkage, remote control, and equipment status management. It supports multi-terminal viewing on both mobile and PC terminals, enhancing operation and maintenance efficiency as well as response speed.

Solution Advantages

All-round perception and remote monitoring: Real-time monitoring and graphical display of distribution station environment, power parameters, equipment operation status, etc., intelligent alarm for abnormal status and support for multi-channel notification, improve the initiative and preventability of operation and maintenance.

Edge computing and intelligent linkage: The All-in-One edge computing gateway has the ability of preliminary analysis and local linkage, and can perform emergency actions (such as power outages and alarm linkage) nearby when an emergency occurs, shortening the response chain.

Platform centralized management and data precipitation: Supports unified access and management of multiple sites, realizes unified view of equipment assets, event records, operation and maintenance log archiving, etc., and promotes digital asset management and traceability.

Benefits

Digitalized O&M

Effectively improves the intelligence level of distribution stations, transforming the conventional passive and manual operation and maintenance mode into a modern digital operation and maintenance mode of “real-time online + remote control + intelligent alarm”. Data is visible in real time, operation and maintenance records are traceable, providing data support for management decisions.

Multi-Layered Safety Defense

It not only improves operation and maintenance efficiency and reduces labor costs, but also builds a multi-layer protection system in equipment safety management, environmental monitoring, emergency response, etc., comprehensively enhancing the initiative and controllability of substation operation and maintenance

Unified & Scalable Management

The solution also has unified access and platform capabilities, laying the foundation for unified management of multiple stations and multiple systems in the future.