The mining industry has long been associated with harsh, remote environments that make reliable communication a significant challenge. As the industry continues to evolve with automation and data-driven operations, ensuring reliable and fast connectivity has become crucial. This is where 5G rugged gateways come into play, offering a powerful solution to connectivity issues that can significantly affect the efficiency, safety, and productivity of mining operations, particularly in remote areas. As a result, these advanced devices ensure that mining operations continue to run smoothly despite the challenges posed by their often isolated locations In this blog, we will explore how 5G rugged gateways are revolutionizing mining connectivity in remote operations, the benefits they offer over traditional technologies, and why they are essential for the future of mining.

Table of contents

- What Are 5G Rugged Gateways and Why Are They Important for Mining?

- Key Benefits of 5G Rugged Gateways for Remote Mining Operations

- How 5G Rugged Gateways Solve Connectivity Issues in Remote Mining Locations

- Why 5G Rugged Gateways Are Better Than Traditional 4G and 3G Technologies

- 5G Rugged Gateways and Their Role in Mining Automation

- Conclusion

- Frequently Asked Questions (FAQs)

What Are 5G Rugged Gateways and Why Are They Important for Mining?

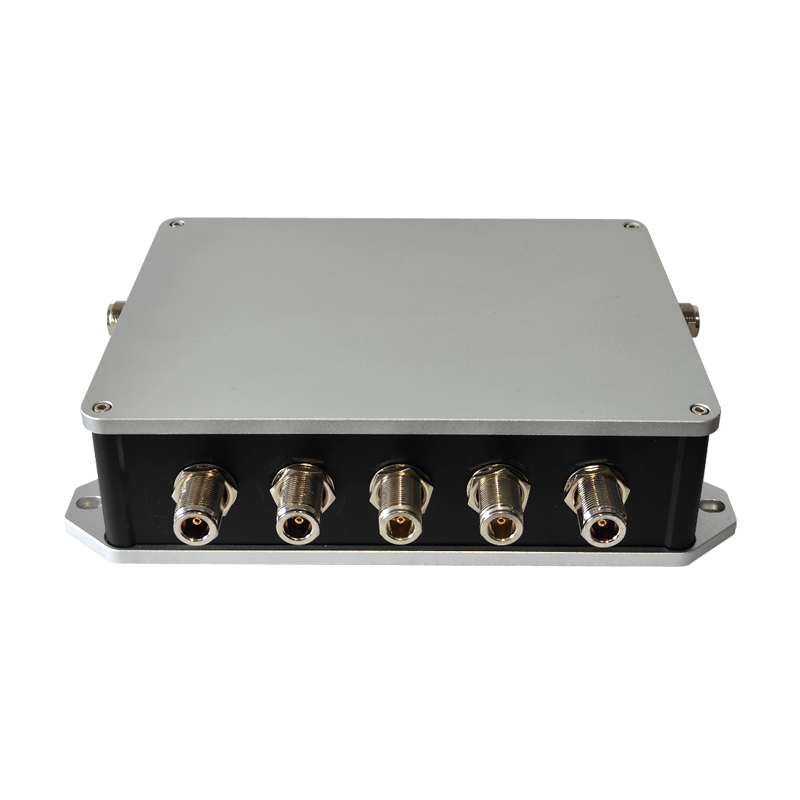

5G rugged gateways are advanced networking devices designed to provide high-speed, low-latency connectivity in environments where standard consumer-grade equipment would typically fail. Moreover, these rugged devices are specifically built to withstand extreme conditions such as high heat, dust, moisture, and shock. As a result, they are ideally suited for use in mining operations, where durability and reliability are critical for maintaining seamless operations.

In mining, where operations often take place in isolated areas with little to no access to traditional communication infrastructure. The introduction of 5G rugged gateways has been a game-changer. Furthermore, they provide the backbone for high-performance connectivity in mines, facilitating automated equipment, remote sensors, and real-time data transmission. Consequently, this is crucial for operations that rely on constant communication between machines and control centers to ensure smooth and efficient workflows.

Key Benefits of 5G Rugged Gateways for Remote Mining Operations

High-Speed Connectivity One of the most significant advantages of 5G rugged gateways over previous technologies like 4G or 3G is their ability to provide high-speed data transmission. The speed of 5G networks allows mining operators to transmit large volumes of data from machines and sensors in real time. This is critical for real-time monitoring, predictive maintenance, and effective decision-making in remote mining operations.

Low Latency for Real-Time Operations Latency is a critical factor in remote mining operations. Low latency ensures that data is transmitted without delay, allowing operators to make timely decisions. With 5G, latency is drastically reduced, making it possible to control autonomous machines, drones, and robotic systems in real-time. This reduction in lag is vital for ensuring safety and improving operational efficiency.

Enhanced Reliability Mining environments can be unpredictable. With factors such as weather conditions, temperature fluctuations, and physical shocks affecting the performance of network equipment. 5G rugged gateways are built to handle these challenges. Their durability ensures that they continue functioning even in the harshest conditions, providing stable and reliable connectivity for mining operations.

Better Scalability As mining operations expand and incorporate more automated systems, the demand for high-quality connectivity increases. 5G rugged gateways support a higher number of simultaneous connections, allowing for better scalability of mining operations. This means that as more machines, sensors, and devices are added to the system. The 5G network can handle the increased load without compromising performance.

Improved Safety One of the most critical aspects of mining is ensuring worker safety. 5G rugged gateways enable the use of remote monitoring tools and sensors that track the conditions of both the mine and the workforce. With real-time data transmission, operators can quickly respond to safety hazards, preventing accidents and ensuring that the mining environment remains secure.

How 5G Rugged Gateways Solve Connectivity Issues in Remote Mining Locations

Mining operations are often located in remote or difficult-to-reach areas, making connectivity a significant challenge. Traditional communication methods such as satellite or terrestrial networks may not always provide the necessary coverage. Especially when mining activities extend deep underground or to the farthest reaches of the mine.

The gateways bridge this gap by offering high-performance connectivity in areas with limited infrastructure. They use advanced wireless technologies to connect even the most isolated mining sites to the internet. Allowing data to flow seamlessly between equipment and control centers. These gateways ensure that remote locations are never out of touch, improving productivity and enabling real-time decision-making.

Why 5G Rugged Gateways Are Better Than Traditional 4G and 3G Technologies

While 4G networks have been sufficient for many industrial applications, they fall short in the demanding environments of remote mining. 5G networks offer several key advantages over 4G and 3G technologies:

Higher Bandwidth 5G networks offer significantly higher bandwidth compared to 4G, which means they can handle a far greater amount of data at once. In a mining context, this enables large-scale data collection from multiple sensors, cameras, and machines. It allows for faster data transmission, which is essential for operations relying on real-time analytics.

More Reliable Coverage5G rugged gateways are built to provide more consistent and reliable coverage, even in areas with challenging topography or extreme weather conditions. While 4G networks may drop in certain remote areas, 5G networks are designed to maintain a stable connection, ensuring that mining operations remain connected no matter where they are located.

Support for More Devices As mining operations continue to evolve, the number of devices used in the field increases. 5G networks can handle more devices simultaneously, ensuring that each device (whether it’s an autonomous truck, drill, or monitoring sensor) remains connected. This capability is crucial as mining operations become increasingly automated and data-driven.

Faster Response Times The low latency of 5G rugged gateways ensures that data can be transmitted and processed quickly. This is critical for controlling automated equipment such as drones and autonomous vehicles. Where even a slight delay in communication can cause safety issues or operational inefficiencies.

5G Rugged Gateways and Their Role in Mining Automation

Automation is the future of mining, and 5G rugged gateways play a crucial role in enabling it. As more mining companies invest in automated systems, the need for robust and fast communication becomes even more important.

It enable remote control of mining vehicles, equipment, and robots, allowing mining companies to reduce human labor in dangerous environments. These gateways support the transmission of real-time data from autonomous trucks, excavators, and drilling machines. Allowing operators to make split-second decisions based on accurate, up-to-date information.

In addition, 5G rugged gateways support predictive maintenance by continuously collecting and transmitting data from machines. This data helps operators identify potential issues before they cause equipment failure, reducing downtime and improving overall productivity.

Conclusion

The introduction of 5G rugged gateways into mining operations marks a significant advancement in mining connectivity. These devices solve many of the connectivity challenges faced by the industry. Offering high-speed, low-latency networks that enable remote monitoring, automation, and real-time decision-making. With their ability to withstand extreme conditions and support more devices, 5G rugged gateways are set to become an integral part of the mining industry’s digital transformation. By improving connectivity, efficiency, and safety, they are shaping the future of remote mining operations.

Frequently Asked Questions (FAQs)

They offer significantly higher bandwidth, lower latency, and greater reliability compared to 4G, making them the superior choice for mining operations. 5G networks can handle larger amounts of data, provide more reliable coverage in remote locations, and support more devices simultaneously, all of which are essential for modern mining operations.

Yes,they are suitable for all types of mining operations, from underground mining to open-pit mining. These devices are designed to withstand harsh environmental conditions such as extreme temperatures, high humidity, and physical shock, making them perfect for even the most challenging mining environments.

They enable the remote monitoring of equipment and real-time data transmission, allowing operators to manage mining operations remotely. They also support automation by providing fast, reliable communication between autonomous vehicles and control centers, ensuring that equipment can be operated and adjusted in real time.

5G rugged gateways are built to withstand extreme conditions, including high temperatures, dust, moisture, and physical shocks. Their durability ensures that they continue to function reliably even in harsh mining environments, providing stable and continuous connectivity.

Yes, by enabling remote monitoring and automation, they help reduce labor costs and minimize downtime. Additionally, they support predictive maintenance, allowing operators to address potential equipment issues before they result in costly repairs or production delays.