TruGem Unmanned Mining Truck Solution bases on RTK centimeter level high precision positioning tech empower mines.

Background

With the rapid development of the mining industry, the mining scale of open-pit mining areas is constantly expanding, which puts forward higher requirements for the operation efficiency and safety of mine trucks. The High-precision positioning solutions based on GNSS (GPS/Galileo/GLONASS/BDS) RTK technology provides customers with a more efficient, safe and reliable unmanned driving operation experience.

Challenges

Large positioning error

Conventional mine car positioning methods are easily affected by environmental interference, resulting in large positioning errors and affecting the accuracy of driving trajectories.

Many safety hazards

Inaccurate positioning can easily lead to collision accidents, posing a threat to the life safety of workers in the mining area.

Low operating efficiency

Operation errors caused by positioning errors waste a lot of time and resources and reduce the operating efficiency of mine cars.

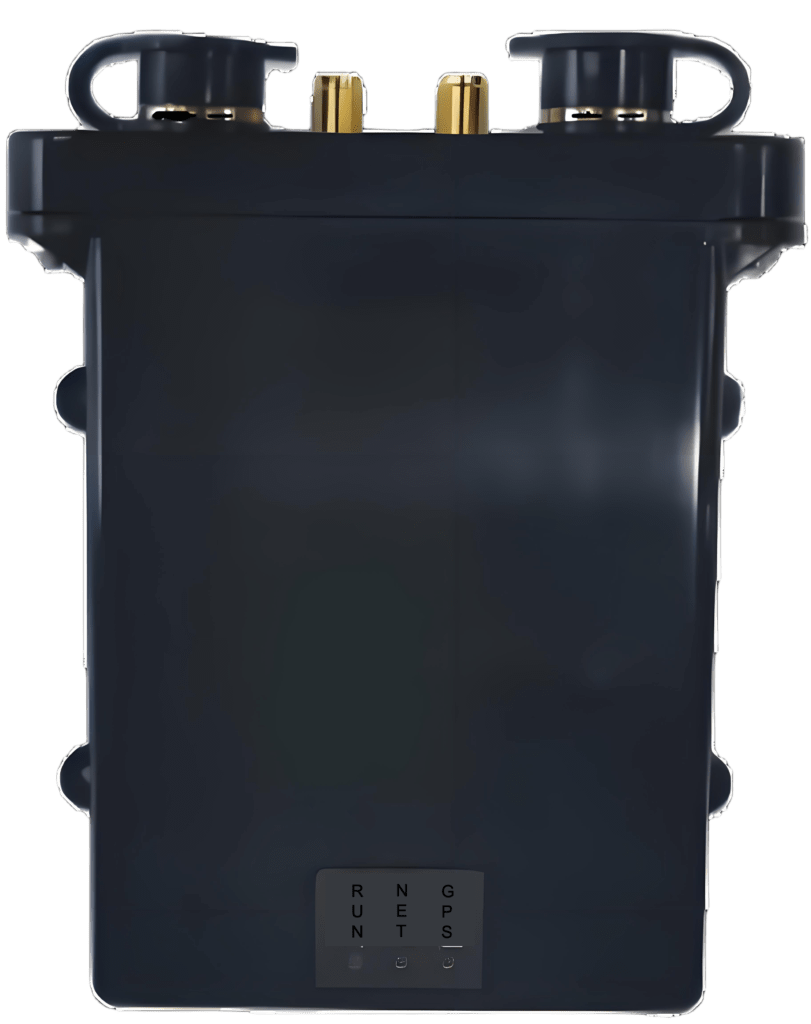

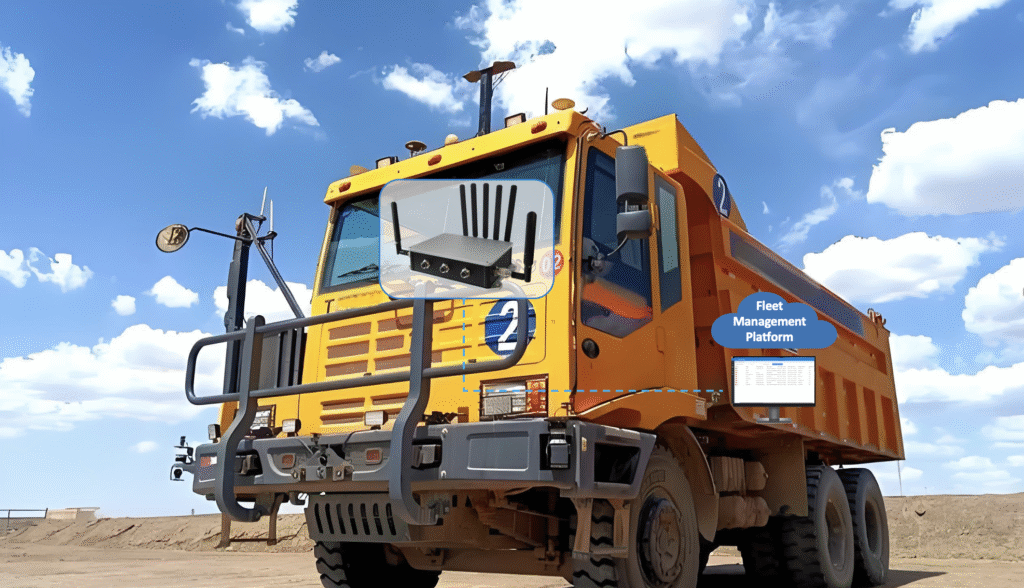

Unmanned Mining Truck Solution

Installing the N506 series high-precision vehicle gateway in the unmanned mining truck can achieve centimeter-level precise positioning. The gateway receives satellite (GPS/Galileo/GLONASS/BDS) signals and uses differential algorithms to correct positioning errors, ensuring that the mining truck maintains an accurate driving track in the complex and changing mining environment. It also effectively avoids collision accidents caused by positioning errors and improves the safety of mining operations. Accurate positioning information helps mining trucks achieve autonomous navigation and assist intelligent scheduling, reducing operational errors and time waste, and improving operational efficiency.

Solution Advantages

High-precision positioning technology: The advanced differential positioning technology is used to achieve centimeter-level precise positioning, which is superior to traditional positioning methods.

Strong anti-interference ability: The gateways has strong anti-interference ability and can maintain stable positioning performance in complex and changeable mining environments.

Easy to install and deploy: The gateways are compact and easy to install, and can be quickly deployed in unmanned mining trucks, reducing implementation difficulty and cost.

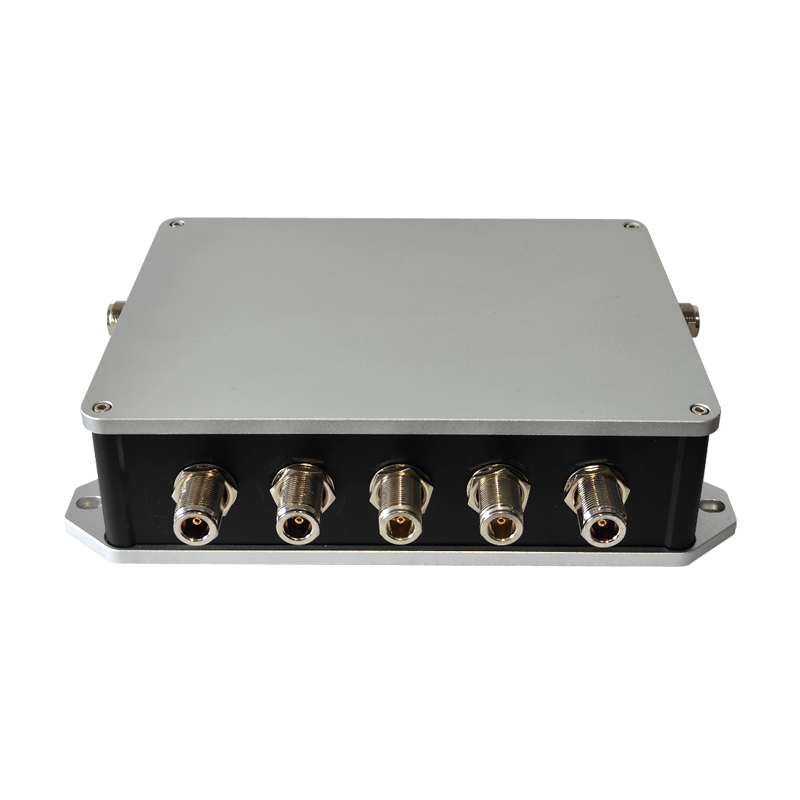

Rich interfaces: M12 8-pin Ethernet port, RS232/RS485, optional USB, etc., by connecting multiple peripherals to expand the vehicle network.

Benefits

Improve the safety of mining operations

Through high-precision positioning, collision accidents are effectively avoided, ensuring the safety of mining workers.

Improve the efficiency of mining vehicles

Accurate positioning information helps mining vehicles to achieve fast and accurate operations, improving overall operating efficiency.

Reduce operating costs

Reduce operating errors and time waste caused by inaccurate positioning, and reduce the operating costs of mining areas.

Discover the power of AIoT, Explore our solutions.

Get started with TruGem and experience the best customer service.