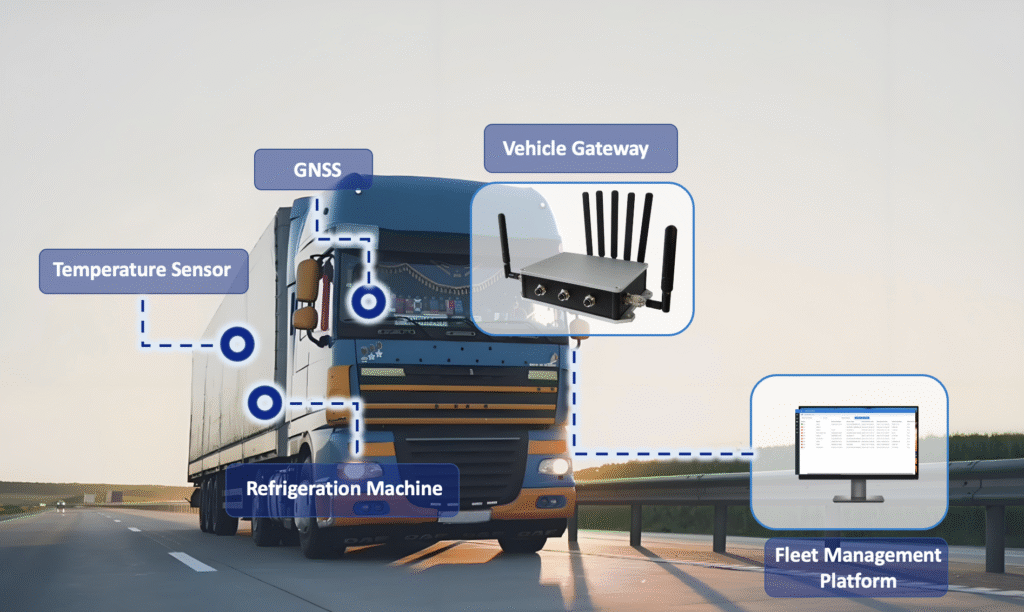

TruGem’s smart cold chain transportation solution based on the vehicle gateway N506 and fleet management platform realizes real-time monitoring and remote control of the refrigeration machine status, vehicle location and environmental parameters, and is suitable for transportation scenarios such as trains and roads.

Background

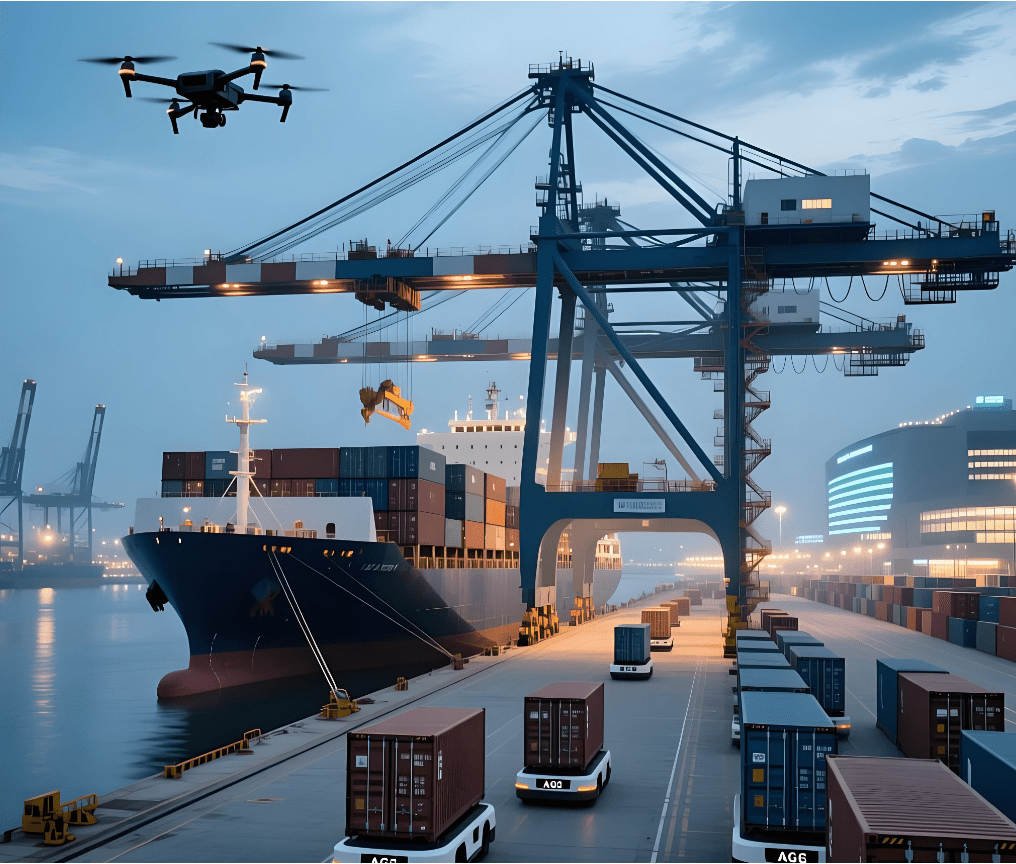

In industries such as medicine, fresh food, and dairy products that have extremely high requirements for temperature control, cold chain transportation has become a core link to ensure the quality and safety of goods. However, the cold chain transportation chain is long, with many links and a complex environment, which not only puts higher requirements on equipment communication, data collection, and remote management, but also challenges the transparency, safety, traceability, and real-time performance of the transportation process. In order to achieve a comprehensive upgrade of smart cold chain transportation, a stable, efficient, and intelligent remote communication and monitoring system must be established.

Challenges

There are many problems with traditional cold chain transportation and operation & maintenance management.

Low transparency in the transportation process

Traditional cold chain monitoring relies on manual checks and delayed data, making it hard to track equipment and environment in real time, reducing visibility and trust.

Cargo safety is hard to guarantee

Undetected temperature shifts, door or fuel issues timely may damage sensitive cargo like vaccines or meat, leading to major losses.

Delayed data and slow alerts

Delayed data uploads and alarm responses hinder timely issue detection, slow down maintenance, and raise operational risks.

Unstable and inaccurate vehicle positioning

Traditional GPS often fails in tunnels and remote areas, making it hard for logistics firms to track cold chain vehicles and ensure route compliance.

High operating costs

Manual checks are costly and inefficient for large-scale scheduling, while poor energy control and frequent downtime raise O&M costs.

Solution

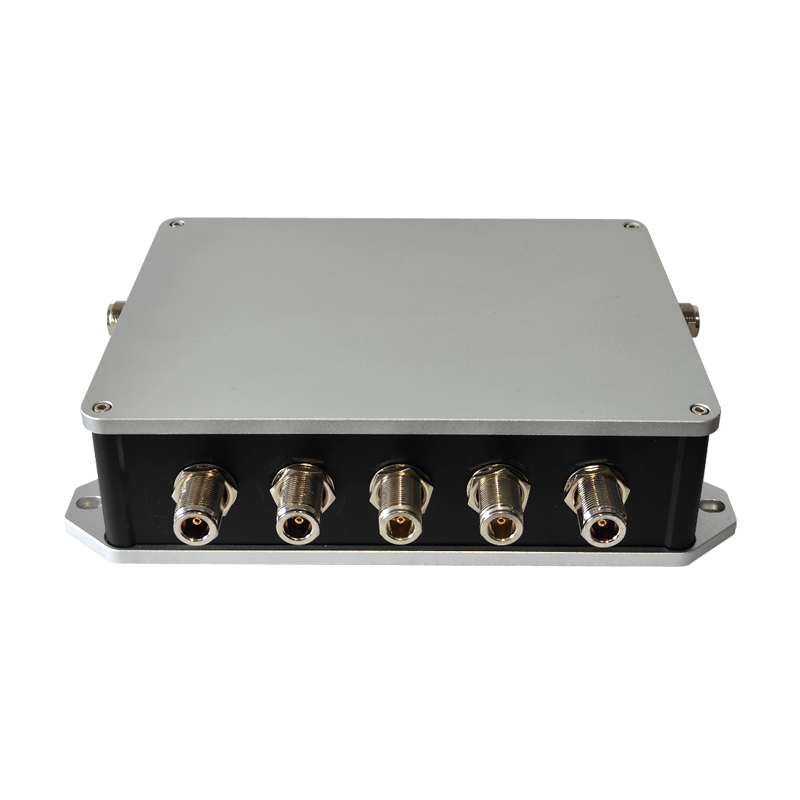

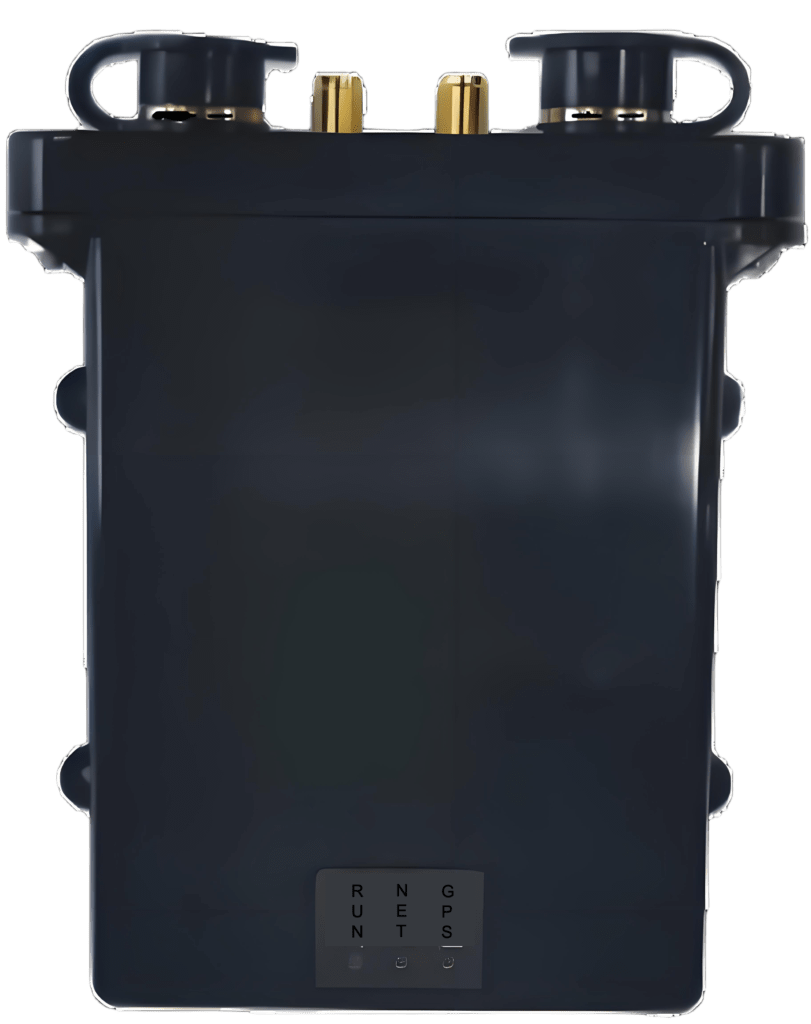

TruGem smart cold chain transportation solution uses the 5G vehicle gateway N506 as the core communication hub, and connects to temperature and humidity, oil level, door magnetic sensors, cold machine controllers, etc. through serial ports such as RS485/RS232 to achieve real-time collection and remote control of cold machine status and environmental data. All data is uploaded to the fleet management platform through the 5G/4G network, which can support functions such as cold machine start and stop control, abnormal alarm, and trajectory playback. The system also has high-precision GNSS(GPS/BDS) RTK real-time positioning, which optimizes energy consumption while ensuring full-process monitoring and improving the intelligent management level of cold chain transportation.

Benefits

Achieve full transparency of the transportation process

Let managers and customers know the status of cold chain transportation at any time and improve service trust.

Comprehensively protect the safety of goods

Multiple sensors work together to warn of abnormalities in the first time and ensure a stable storage environment for materials.

Improve operation and maintenance efficiency

Remote control and online monitoring greatly reduce the need for manual inspections and reduce operation and maintenance costs.

Strengthen scheduling and compliance management

High precision positioning combined with trajectory playback to achieve efficient scheduling and compliance path monitoring.