As ports modernize their operations, AI video analytics for container fire prevention is becoming indispensable. And in this transformation, the concept of Predictive Port Safety emerges as the first line of defense—not after flames appear, but long before risks escalate into incidents. This shift matters because container fires rarely begin with visible flames; instead, they start with small, hidden signals inside sealed containers, at high-stacked positions, or during nighttime low-light operations. Traditional fire detection fails here, but AI’s ability to analyze micro-patterns, heat drift, deformation, and behavior chains makes truly proactive safety achievable.

Table of contents

- Why Container Fires Are So Hard to Detect

- AI Video Analytics Is Not About Detecting Fire—It’s About Understanding Fire Evolution

- Why Ports Are the Perfect Environment for Predictive Fire Prevention

- How AI Turns Invisible Risks Into Visible Patterns

- From Firefighting to Predicting Fire: A New Safety Paradigm

- The Future: Toward a Self-Healing Port Yard

- Conclusion

Why Container Fires Are So Hard to Detect

Typical fire detection focuses on visible flames, smoke, or heat signatures, yet port fires follow a completely different evolution. The earliest danger signals are not visible and often occur in:

- The sealed interior of containers

- Mid-level stacks with camera blind spots

- Night operations with minimal lighting

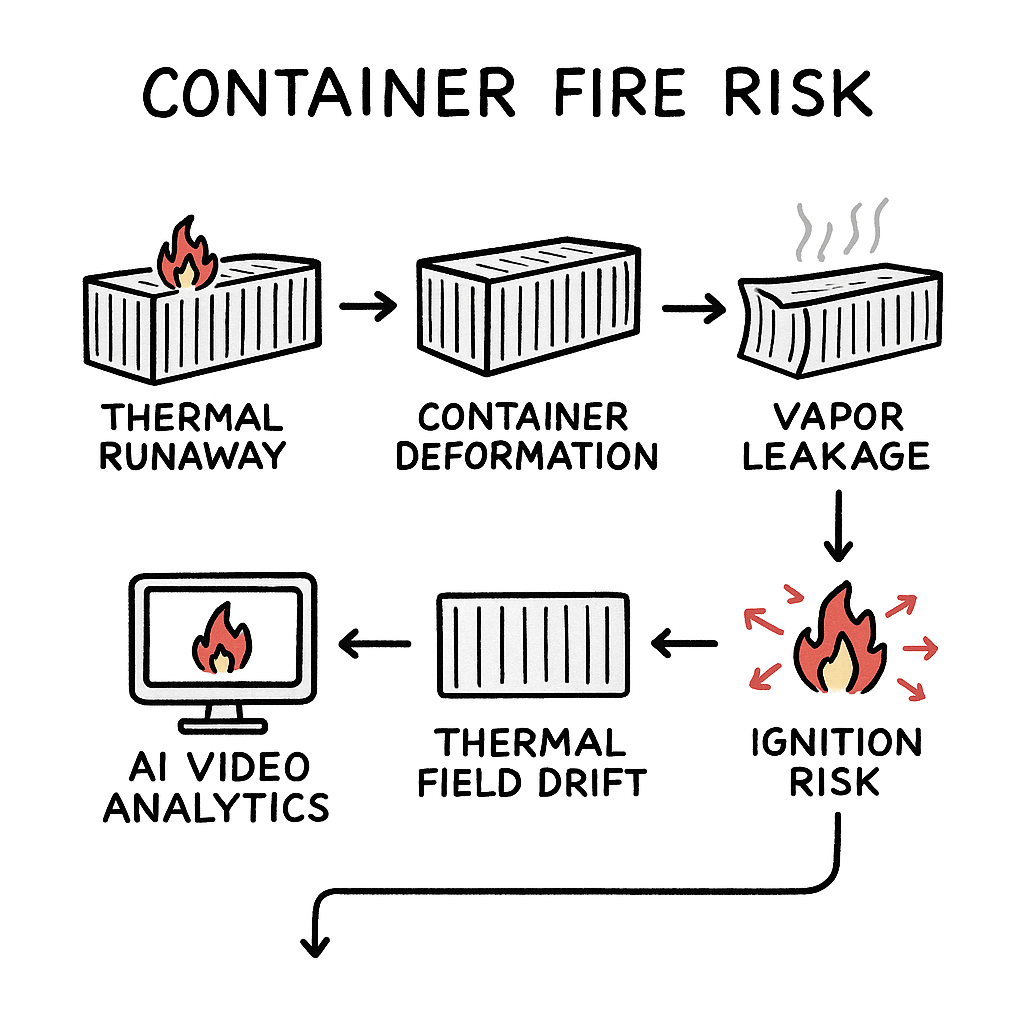

Moreover, container fire development usually follows a hidden chain reaction:

Battery thermal runaway → micro heat build-up → structural deformation → vapor leakage → thermal field drift → ignition

AI video analytics excels at identifying these pre-fire anomalies—long before traditional systems react.

AI Video Analytics Is Not About Detecting Fire—It’s About Understanding Fire Evolution

Modern AI models do not simply classify smoke or flames; they detect:

a. Thermal Field Drift (Micro Heat Anomalies)

Standard RGB cameras can reveal:

- Air refraction distortions

- Reflectivity changes

- Gradient pattern anomalies

- Subtle shimmering from heat waves

This technique acts like a visual thermal imager powered entirely by AI.

b. Container Micro-Deformation Detection

Early thermal runaway causes:

- Slight bulging of container doors

- Minute distortions at lock points

- Structural stress patterns

AI uses sub-pixel deformation algorithms—something humans cannot perceive.

c. Behavior Chain Analytics

Before fire ignition, AI detects environmental and operational patterns such as:

- AGVs and trucks subtly avoiding a specific bay

- Frequent abnormal glints or steam-like haze

- Repeated heat-related warnings in the same row

- Unusual night-time brightness fluctuations

This allows AI to understand how the environment behaves before fire appears.

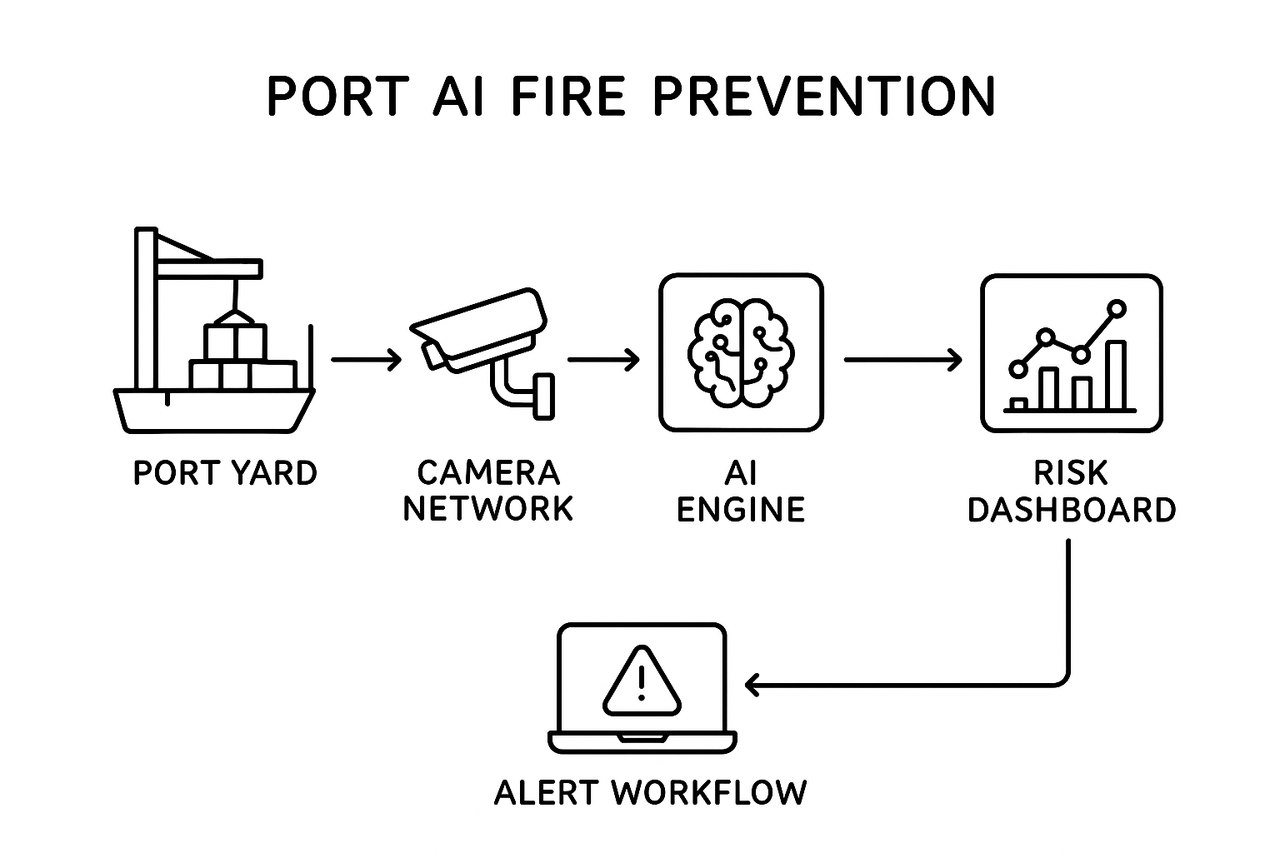

Why Ports Are the Perfect Environment for Predictive Fire Prevention

Ports naturally support AI-based predictive safety because they feature:

High camera density

Providing the visual data needed for training and inference.

Operational regularity

Predictive models learn structured behaviors more easily in ports than in cities.

High-risk cargo proportion

Lithium batteries, chemicals, and electronics raise the urgency for predictive analytics.

End-to-end digital integration

Ports can quickly close the loop from detection → alert → dispatch → workflow changes.

This makes ports ideal for AI-driven early fire prediction.

How AI Turns Invisible Risks Into Visible Patterns

| Data Source | AI Detects |

| RGB Cameras | deformation, glare anomalies, airflow distortion |

| Thermal Cameras | heat gradients, hot spots, diffusion paths |

| Vehicle/AGV Paths | avoidance pattern changes |

| VOC Sensors | early gas leakage signals |

| Yard Operation Logs | hazardous cargo distribution |

When combined, AI produces a real-time risk probability map of the yard.

From Firefighting to Predicting Fire: A New Safety Paradigm

Traditional Approach:

- Detect smoke

- Detect flames

- Detect elevated temperature — Too late.

AI Predictive Approach:

- Detect micro heat drift

- Detect internal stress changes in containers

- Detect unusual equipment behavior

- Detect environmental anomalies

- Forecast: Possible ignition in 20–40 minutes

AI creates a new safety paradigm where:

- Incidents drop dramatically

- Risks remain continuously visible

- Response becomes faster and more targeted

- Yard operations adapt dynamically to risk levels

This is transition from reaction to prediction.

The Future: Toward a Self-Healing Port Yard

AI will soon enable:

- Risk scoring for every container

- Automated reallocation of high-risk cargo

- Robot dispatch for hotspot verification

- Automated isolation of high-risk bays

- Dynamic path planning for AGVs

- Real-time “yard health visualization”

In such a system, safety becomes autonomous.

Conclusion

AI video analytics does far more than detect fire—it anticipates the pattern of danger before traditional sensors notice anything. In ports where risks remain largely invisible, AI becomes:

The invisible shield protecting workers, cargo, and global supply chains.

And this shift marks a new era of Predictive Port Safety.