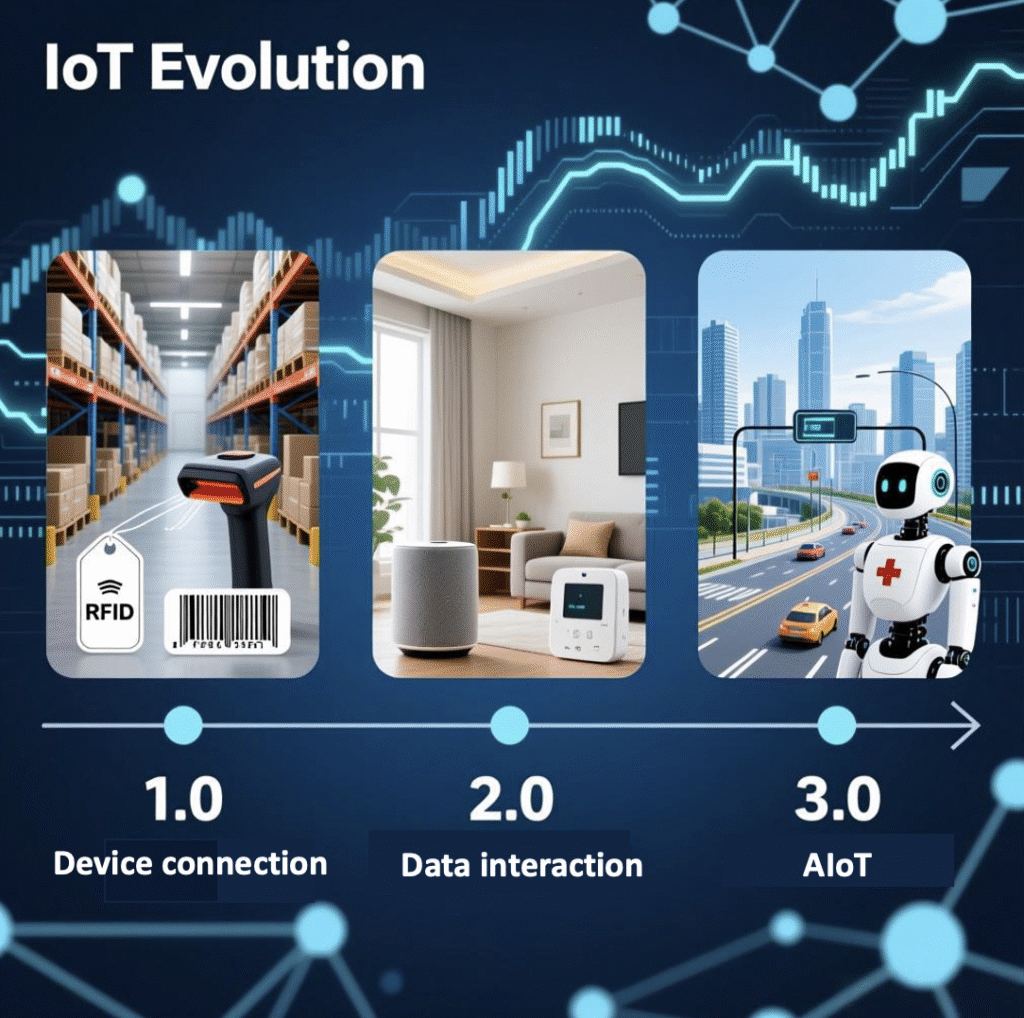

For more than a decade, the Internet of Things (IoT) has focused primarily on connecting devices and collecting data. Sensors were deployed, platforms were built, and enterprises invested heavily in digital infrastructure with the expectation that data alone would unlock new business value. Yet millions of connected devices later, many organizations have realized a critical truth: raw data does not automatically produce insights. Today, industries are stepping into the next stage of IoT evolution—where the focus shifts from simple data collection toward data understanding, intelligence, and autonomous decision-making. This shift marks the emergence of AIoT, the tight integration of IoT with artificial intelligence, and the rise of Data Intelligence as a core competitive advantage.

In this new era, data becomes meaningful only when it can be analyzed, contextualized, and transformed into actionable decisions. This evolution redefines what modern IoT systems should deliver and reshapes the architecture from edge to cloud. As organizations move forward, they will rely on IoT Analytics, intelligent automation, and the seamless Edge-to-Cloud Continuum to drive real-world outcomes.

This blog explores how IoT is transitioning from data collection to insight generation, why this transformation is essential, and what enterprises need to build the next generation of intelligent systems.

The Limitations of Traditional IoT: Why Data Alone Is Not Enough

Early IoT deployments emphasized connectivity. The main objective was simple: gather as much data as possible from distributed assets and send it to the cloud. This architecture worked when data volumes were manageable and analytics expectations were low. However, as deployments grew, several limitations emerged:

Overwhelming Data Volume

Billions of sensors now generate far more data than traditional systems can process effectively. Much of this data is repetitive or low-value, resulting in:

- unnecessary transmission costs

- overloaded cloud platforms

- delayed analytics

- reduced operational visibility

Although organizations collected more data than ever, they often struggled to extract real insights.

Lack of Context and Interpretation

Sensor data without context cannot describe real operational conditions. A temperature reading of 85°F or a vibration threshold crossing means nothing without understanding:

- what equipment it belongs to

- normal operating states

- environmental conditions

- historical patterns

Traditional IoT treated all data equally, missing the opportunity to identify anomalies, anticipate failures, or guide decisions.

Slow, Cloud-Dependent Decision Cycles

When data must travel from the device to the cloud and back before action is taken, latency becomes a significant barrier. In manufacturing, energy, transportation, or public safety, milliseconds matter. Traditional cloud-centric models could not meet these real-time operational demands.

No Built-In Intelligence

Most IoT systems only monitored and reported—they did not interpret or decide. Human operators still performed the majority of analysis and response, limiting scalability and speed.

These limitations have driven a global shift toward AIoT, where intelligence, analytics, and decision-making move much closer to the data source.

The Rise of AIoT: When Data Meets Intelligence

AIoT—the convergence of artificial intelligence with IoT—is the natural and necessary next step. Instead of merely sensing and transmitting data, AIoT devices and platforms can understand, predict, and act.

This shift is powered by several technological and market developments:

Edge AI for Real-Time Decision-Making

AI algorithms can now run directly on edge devices, enabling:

- local anomaly detection

- pattern recognition

- predictive maintenance

- instant alerts and control

This eliminates latency and allows decisions to happen in milliseconds.

Data Intelligence as a Core IoT Value

Enterprises now view Data Intelligence—the ability to transform data into insights—as more valuable than connectivity itself. Instead of sending 100% of data to the cloud, organizations prioritize extracting meaning and only transmitting what is relevant.

Growth of IoT Analytics Platforms

Modern IoT Analytics platforms integrate AI, machine learning, and domain models, enabling:

- advanced trend detection

- operational optimization

- cross-site benchmarking

- automated reporting

Analytics has moved from retrospective dashboards to predictive and prescriptive intelligence.

Emergence of Edge-to-Cloud Continuum

IoT architecture is no longer “edge vs. cloud.” Instead, it is a dynamic Edge-to-Cloud Continuum, where data processing is distributed optimally:

- Edge handles real-time, local intelligence

- Cloud manages long-term storage, advanced AI training, and cross-system analysis

This continuum creates a fluid, efficient system capable of delivering high-quality insights at scale.

In this new paradigm, IoT becomes not a passive data collector but an active intelligence generator.

From Raw Data to Insight: What the Future Architecture Looks Like

The next generation of IoT systems will follow a clear structure centered around intelligence, not just connectivity. The key components include:

Intelligent Edge Devices

Modern edge gateways and smart sensors incorporate:

- high-performance CPUs or NPUs

- built-in machine learning inference

- edge data filtering

- local rule engines

- secure communication modules

These devices no longer wait for cloud instructions; they execute decisions immediately.

Unified Edge-to-Cloud Data Pipeline

A strong Edge-to-Cloud Continuum ensures efficient data movement:

- critical data is processed locally

- enriched data is uploaded for deeper analytics

- low-value data can be discarded

- metadata helps build long-term patterns

This approach reduces cloud load and boosts real-time responsiveness.

AI-Driven IoT Analytics Layer

Modern IoT Analytics platforms integrate:

- machine learning

- digital twins

- root-cause analysis

- time-series intelligence

- domain-specific model libraries

Instead of merely presenting dashboards, they guide decisions with actionable insights.

Autonomous Control and Decision Engines

The ultimate goal is to enable systems to act without human intervention:

- automatically adjusting machine settings

- triggering maintenance workflows

- optimizing energy consumption

- responding to safety risks

- predicting failures before they occur

This is where AIoT delivers its true value—turning operational environments into self-managing systems.

Why Insight-Driven IoT Is Becoming a Business Imperative

As industries become more digital and competitive, several pressing demands accelerate the shift from data collection to insight generation.

Rising Operational Complexity

Manufacturing, energy, logistics, utilities, ports, and smart cities all rely on interconnected systems. Manual monitoring cannot cope with:

- the scale of assets

- unpredictable events

- real-time optimization demands

AIoT provides the intelligence needed to manage growing complexity.

Increasing Pressure for Efficiency

Inflation, raw material shortages, and energy volatility force enterprises to maximize efficiency. IoT Analytics can:

- reduce downtime

- optimize asset utilization

- cut energy waste

- streamline processes

Insight generation becomes a direct driver of profitability.

Heightened Safety and Compliance Requirements

Industries must detect problems early and act immediately. Insight-driven IoT allows:

- early hazard identification

- automated intervention

- continuous compliance monitoring

- reduced reliance on human operators

This reduces risk and improves workplace safety.

Demand for Predictive Maintenance

Companies can no longer rely on “run to failure.” Predictive insights prevent:

- catastrophic breakdowns

- production losses

- excessive maintenance costs

AI-enabled Data Intelligence transforms maintenance from reactive to proactive.

In every industry, insight generation is no longer optional—it is a competitive necessity.

Practical Use Cases: What Insight-Driven IoT Looks Like in Action

The shift toward Data Intelligence is already accelerating across sectors. Here are real-world examples of how organizations turn raw data into actionable insights.

Manufacturing: From Monitoring to Optimization

Traditional IoT monitored machine status. AIoT enables:

- real-time defect detection

- predictive maintenance

- process optimization

- automated quality alerts

Factories become self-correcting systems that continuously improve performance.

Energy & Utilities: Enhanced Reliability and Grid Intelligence

Utilities leverage IoT Analytics and Data Intelligence to:

- detect equipment anomalies

- optimize load balancing

- prevent outages

- coordinate distributed energy resources

The Edge-to-Cloud Continuum allows decisions to occur instantly at the grid edge.

Transportation & Logistics: Smarter, Safer, Faster

In logistics and fleet management, insight-driven IoT supports:

- route optimization

- fuel efficiency analytics

- predictive vehicle maintenance

- cargo integrity monitoring

AIoT ensures the entire transportation ecosystem runs more efficiently.

Smart Cities: Autonomous Public Services

Cities apply AIoT to:

- manage traffic flows

- reduce energy consumption

- monitor air quality

- detect safety incidents

Decisions happen at the edge, making city operations more responsive.

Enabling Technologies That Power the Next Stage of IoT Evolution

To transition from data collection to insight generation, enterprises must leverage several enabling technologies.

Edge AI Computing

Running AI models at the edge enables:

- ultra-low latency

- local decisions

- data privacy

- reduced cloud dependency

It is the foundation of modern AIoT.

Advanced IoT Analytics Engines

Next-generation analytics platforms provide:

- deep time-series insight

- anomaly detection

- trend forecasting

- automated decision-support

Analytics becomes the heart of Data Intelligence.

Cloud AI and Long-Term Learning

The cloud remains essential for:

- training machine learning models

- aggregating multi-site data

- conducting large-scale IoT Analytics

- visualizing performance trends

The synergy between edge and cloud strengthens the entire system.

Digital Twins

Digital twins simulate assets, systems, or entire facilities, enabling:

- faster diagnostics

- virtual testing

- optimized configurations

- scenario-based decision-making

This accelerates insight generation and reduces operational risk.

Designing for Intelligence: A Blueprint for the Future of IoT

To succeed in the next stage of IoT evolution, enterprises should redesign their IoT strategy with intelligence at the center. Key principles include:

Process Data Locally First

Send only meaningful, contextualized data to the cloud. Let the edge act as the first stage of analysis.

Build a Unified Edge-to-Cloud Continuum

Avoid siloed systems. Architect seamless collaboration between edge and cloud analytics.

Integrate AI From the Start

AI should be built into the IoT stack—not added later as an enhancement.

Redefine KPIs Around Insight, Not Data Volume

Measure success based on:

- accuracy of predictions

- reduction in downtime

- operational optimization

- speed of response

Insight, not data, becomes the primary metric.

Prioritize Security Across the Pipeline

As intelligence increases, so must security. Protect:

- data

- device firmware

- analytics models

- decision-making engines

Security must span the entire Edge-to-Cloud Continuum.

Conclusion: Insight Generation Defines the Future of IoT Evolution

The evolution of IoT is clear: The value is no longer in data collection—it is in intelligence, insight, and action.

AIoT, Data Intelligence, IoT Analytics, and the Edge-to-Cloud Continuum together form the foundation of this new era. Organizations that embrace these capabilities will transform operational efficiency, strengthen decision-making, and unlock unprecedented value from their IoT investments.

As the world becomes more connected, the real competitive advantage will belong to companies that can understand their data and turn insight into intelligent action. The next stage of IoT evolution has already begun—and it is defined not by connectivity alone, but by intelligence at every layer.