The integration of AIoT (Artificial Intelligence of Things) technology is revolutionizing the industrial landscape, enabling smarter, safer, and more efficient operations. At a large LNG receiving station, TruGem’s AIoT solution has addressed critical monitoring challenges, leveraging cutting-edge real-time monitoring and intelligent automation technologies. Here’s how the solution works and the transformative benefits it delivers.

Background and Challenges

The LNG receiving station, with an annual processing capacity of 7 million tons, previously relied on camera systems for manual monitoring. This approach posed significant challenges:

- Inefficiency: Manual observation failed to provide timely detection of unsafe behaviors or environmental risks during high-risk operations.

- High Costs: Dependence on human labor increased operational expenses without guaranteeing consistent vigilance.

To address these pain points, the station required a next-generation solution to enhance safety, improve efficiency, and reduce costs.

Customer Requirements

Cost Reduction and Efficiency Improvement

- Transition from manual monitoring to an automated system for smarter resource utilization.

- Lower operational costs without compromising on safety or quality.

Real-time Monitoring

Implement 24/7 real-time monitoring to track personnel actions and environmental conditions continuously.

Proactive Early Warnings

Enable instant alerts for abnormal behaviors or risks to mitigate hazards effectively.

Solution

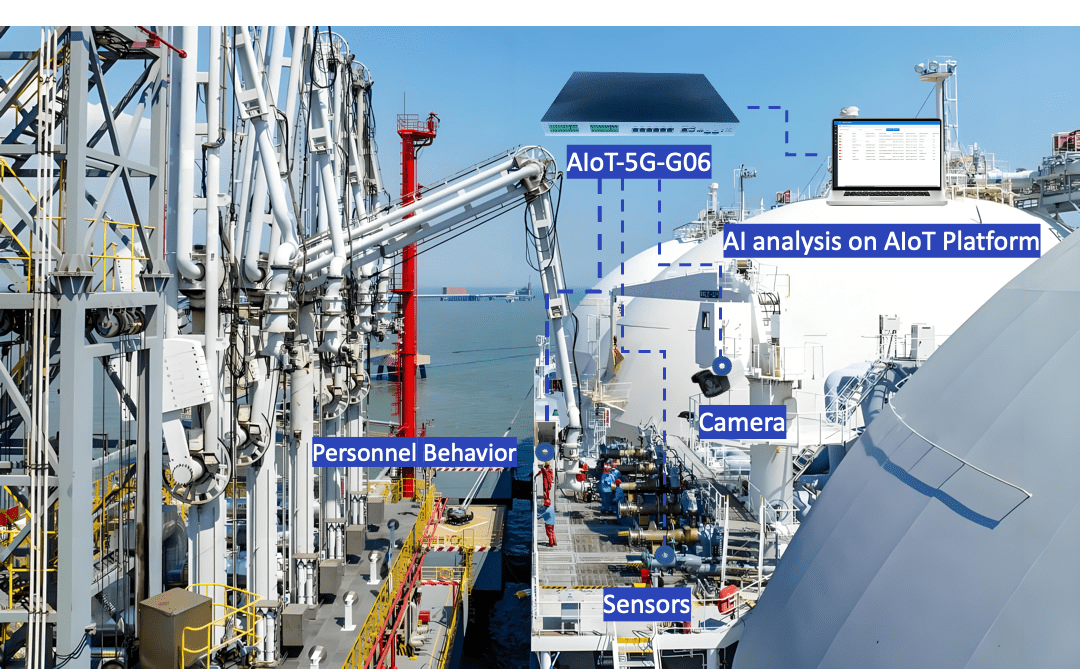

The station deployed TruGem’s AIoT-enabled All-in-One Edge Gateway AIoT-5G-G06 and AIoT Solution to revolutionize its monitoring system. This comprehensive solution integrates advanced video analytics, environmental sensors, and operational intelligence to deliver unmatched oversight and safety.

Key Features of the AIoT Solution:

- Active Warning of Abnormal Situations

- Supports video surveillance channels for continuous real-time monitoring.

- AI-powered intelligent analysis identifies risky activities such as improper use of safety gear or standing under hoisted objects.

- Illegal Operation Supervision

- Recognizes and flags 15 specific unsafe behaviors, including failure to wear protective gloves or neglecting safety ropes during confined space work.

- Seamless Integration with Management Systems

- The system integrates AI video analytics with the operation management system to oversee the entire workflow of hazardous operations.

- Enhanced Environmental Oversight

- Incorporates cellular temperature monitors and other sensors to track critical parameters like cabinet door status or equipment overheating.

- Smart Alerts and Reports

- Provides energy remote surveillance capabilities and instant notifications to supervisors via connected devices.

Benefits:

Significant Monitoring Efficiency Gains

- The workload of manual monitoring decreased drastically, with overall efficiency improved by 320%.

- Automation with AI significantly reduced human intervention, cutting costs.

Proactive Early Warning System

- Round-the-clock real-time monitoring enabled the detection of unsafe situations within seconds.

- Instant notifications ensured swift mitigation of risks.

Improved Handling Efficiency

- Problem identification and response became 12 times faster due to proactive alerts.

- Integration with systems like energy command and security radio improved communication and workflow.

Enhanced Environmental Control

- Additional tools like eagle energy sensors and accelerated concepts in environmental analytics provided granular insights, improving operational safety.

Related Products

More AIoT Applications

AIoT Solution for Wind Power Generation

Integrated real time monitoring, remote management and intelligent analysis and alarm system notification, TruGem AIoT solution increase the safety production efficiency of wind energy generation.

Discover the power of IoT and AIoT, Explore our solutions.

Get started with TruGem and experience the best customer service.