This solution demonstrates how converging mature technologies (5G+PLC) with cutting-edge AI enhancing Industrial Safety & Efficiency, proving that Industry 4.0 transformations can start with operational pain points rather than full-system overhauls.

Client Challenge

Safety Vulnerabilities

Unauthorized personnel entering hazardous zones caused several incidents monthly.

Production Blind Spots

Legacy PLC systems lacked real-time coordination with quality control processes.

Data Fragmentation

Isolated PLC networks prevented centralized monitoring of 120+ production cells.

Solution

A converged architecture combining 5G connectivity, AI vision analytics, and PLC modernization

- Intelligent Safety Monitoring System

- AI-Powered Surveillance:

- Deployed 5G-connected cameras at high-risk zones (press lines/chemical storage).

- Deployed TruGem’s edge computing gateway AIoT-5G-G06 which integrates AI algorithm and can be realized :

- ▶ Personnel Intrusion: Instant alerts when personnel breach geofenced danger areas.

- ▶Personnel Identification: Detecting authorized vs. unauthorized staff.

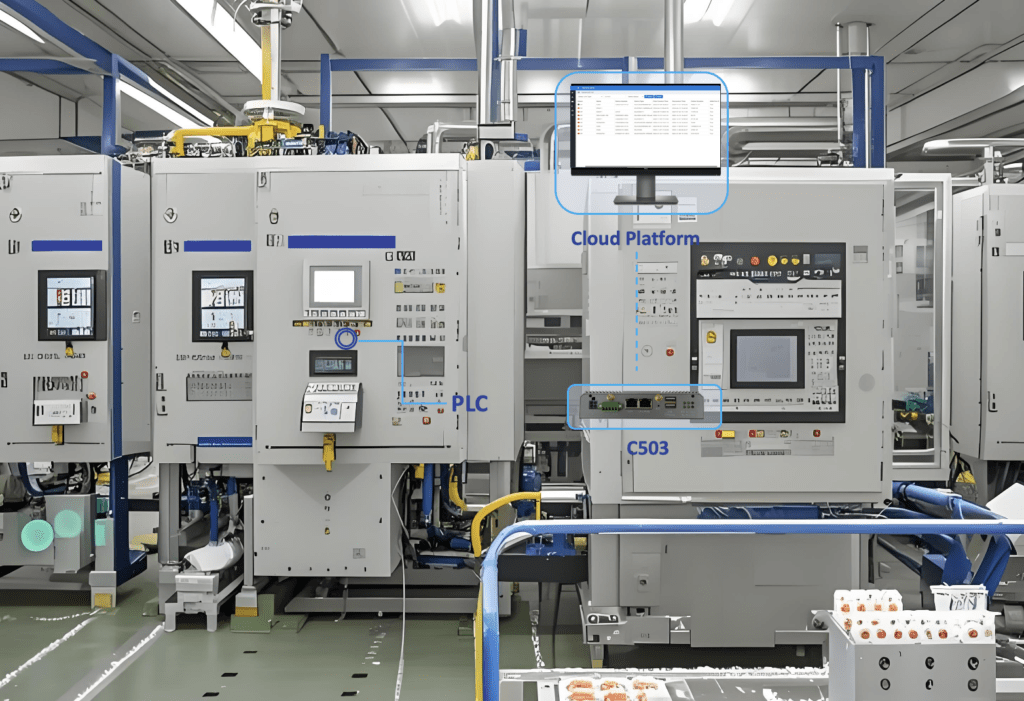

- 5G-Enhanced PLC Network

- Real-Time Data Aggregation:

- Connected PLCs across 4 production halls through 5G industrial routers C503.

- Acquisition real-time data from PLCs and securely transmits it over 5G networks via proprietary protocols to a remote management platform for analysis.

- Edge-Processed Analytics:

- Localized analysis of PLC cycle times to detect abnormal machine states.

- Online real-time monitoring of the production process, fast and efficient feedback

- Centralized Industrial IoT Platform

- Unified Visualization:

- interactive dashboards showing real-time:

- Safety compliance status (green/red zones).

- Machine utilization rates.

- Energy consumption heatmaps.

- interactive dashboards showing real-time:

- Decision Support Tools:

- Automated daily reports comparing PLC performance across shifts.

- Root-cause analysis module for production delays or problems.

Benefits

- Safety Transformation

- 100% detection of unauthorized entries within 0.8 seconds.

- 76% reduction in safety protocol violations.

- Enhancing Industrial Operational Efficiency

- 22% faster response to equipment anomalies.

- 14% improvement in overall equipment effectiveness.

- Data-Driven Culture

- Enabled cross-department access to unified production/safety dashboards.

- Reduced manual data collection efforts by 320 labor-hours/month

Related Products

5G Edge Computing Gateway

Industrial Router